Rotary sifter KEK

For integration into vacuum or positive pressure systems

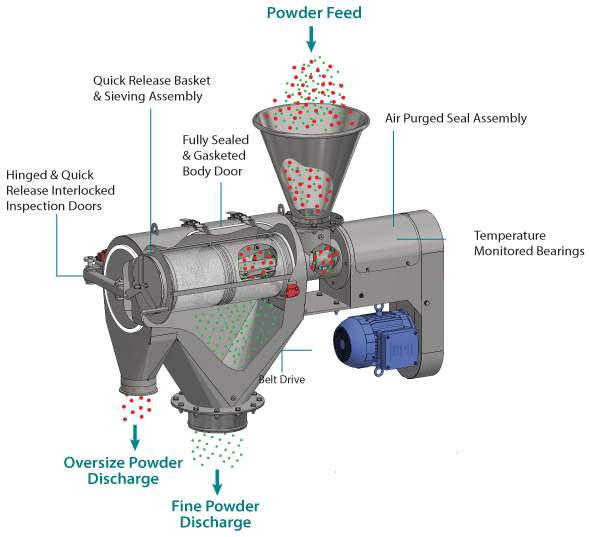

The KEK centrifugal sifter from Kemutec, also known as a rotary sifter, is an industrial solution designed for fast, high-capacity screening of powders and granules. Along with this, its advanced pressure design ensures not only hygienic operation but also efficient size classification for food and pharmaceutical applications.

See rotary sifter KEK in action

The KEK centrifugal sifter delivers fast, high-capacity sifting with excellent hygiene, making it ideal for food production. Also, rapid screen changes in just 30 seconds keep your process efficient and safe.

Alternatively, watch this video on YouTube.

- Overview

- Features and benefits

- Gallery

- Downloads

A centrifugal sifter is used to sift and screen high volumes of material efficiently and at high speed, offering greater performance compared to other sifters used by material producers, such as food, pharmaceutical, and chemical manufacturers.

Moreover, the process of sifting material not only allows for size classification, separating material that isn’t of the required size, but also ensures a proper screening process by removing unwanted material and de-risking powder handling.

A rotary sifter is a common name for this type of centrifugal processing machine, and it can also be referred to as a flour sifter or powder sifter. The sieving process of powders and granules takes place in both gravity-fed and in-line applications, while output with KEK machines can vary from over 90 tons per hour down to just a few pounds.

- Provides size classification of material by sifting and separating out material that isn’t to the required size

- Screens material to remove unwanted material and de-risk from contamination

- Enables high-efficiency, high-speed performance

- Quick and easy to clean, with hygienic cantilever design

- New Paddle assembly design to provide and even more hygienic view

- Cantilever shaft also ensures no oversize bearing or seal

- 30 second screen changes, via easily removable sifter screen for inspection and cleaning

- Additional easier inspection, cleaning and maintenance, due to oversized end door

- Operator friendly – no tools typically required for stripping down and cleaning

- Gravity and inline pneumatic conveying designs

- Available in 7 model sizes to suit different production needs that can process from a few kilograms per hour, to over 90 tons

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.