Gummy applications

Starch-free gummy and jelly manufacturing technology

Coperion offers fully integrated, starch-free gummy and jelly production systems designed to deliver precise dosing, fast changeovers, and hygienic processing. Our advanced technology supports consistent quality and efficiency for gummies and jellies used in food, health, and pharmaceutical industries.

Starch-free solutions for gummy and jelly production

Coperion’s starch-free gummy and jelly production offers a cleaner and more efficient alternative to traditional starch molding. Designed to meet today’s high standards in hygiene, precision, and flexibility, the system eliminates drying steps and reduces contamination risks making it ideal for gummies and jellies in food, health, and pharmaceutical applications.

Whether producing small batches or scaling up, manufacturers benefit from faster changeovers, consistent quality, and the ability to handle heat-sensitive ingredients with confidence. This streamlined process helps future-proof gummy and jelly production and supports innovation.

Adding value throughout the confectionery manufacturing process

Starch-free depositing adds value by allowing multi-colors, center-fills, inclusions, and 3D shapes that enhance gummy and jelly variety. Easy cleaning ensures less downtime while advanced screening and ingredient processing improve hygiene and reduce waste.

The technology brands behind our gummy and jelly solutions

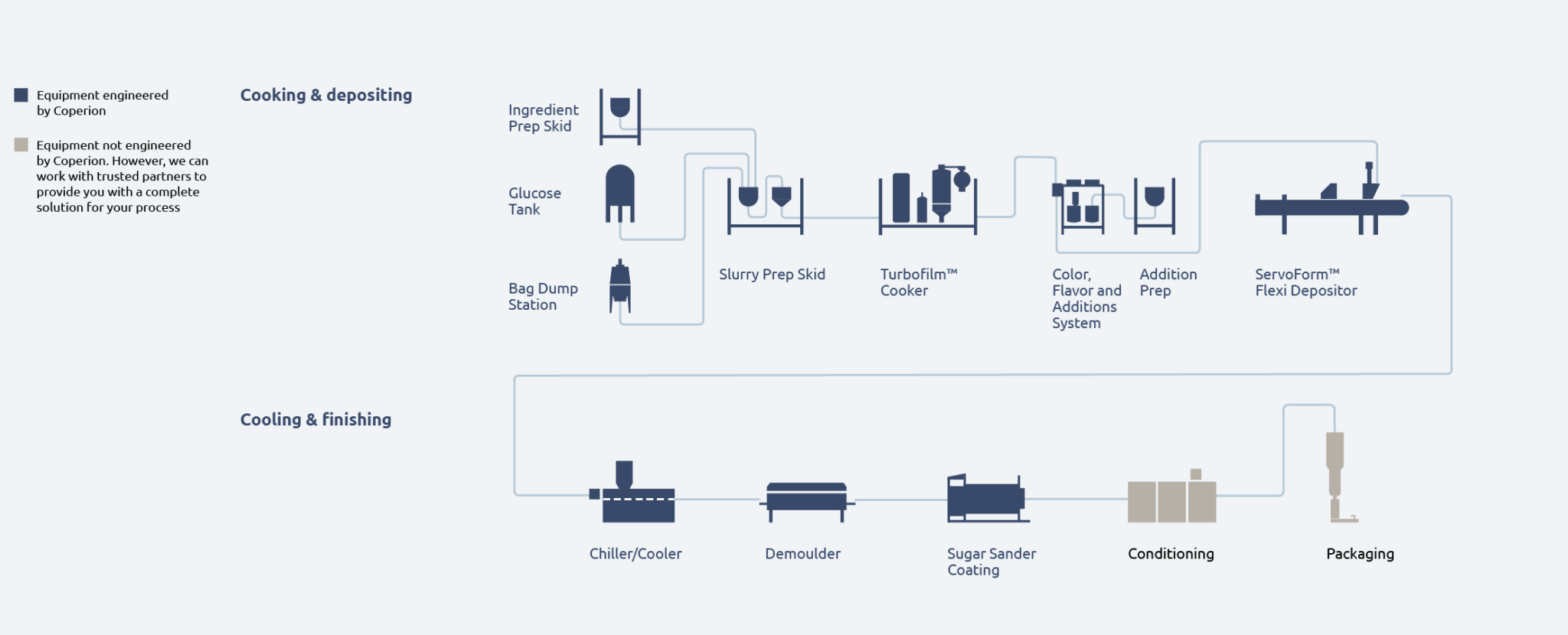

How gummy and jelly production works

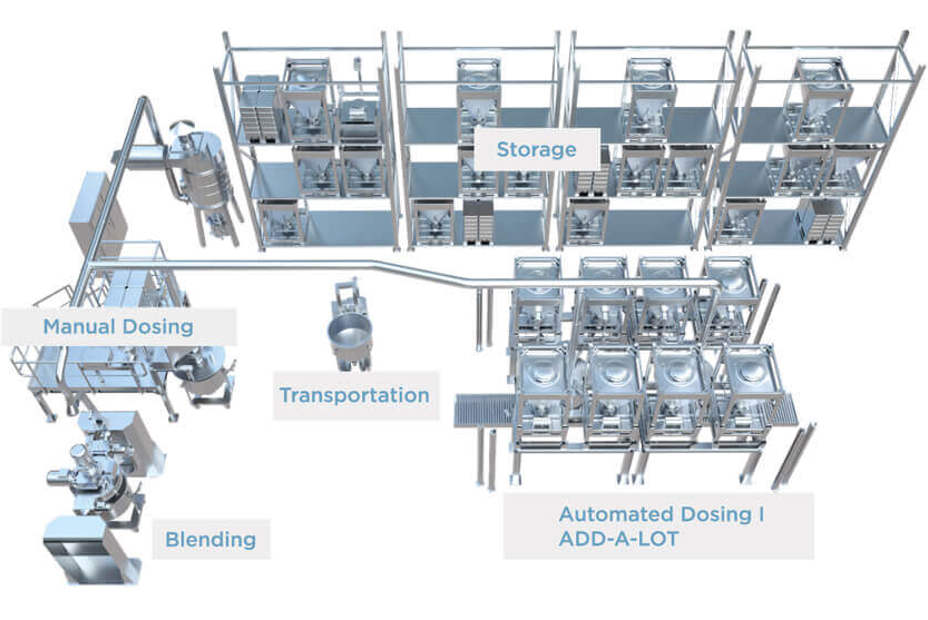

Ingredient handling

Bag dump stations provide a safe, dust-free way to manually add dry ingredients.

For liquid ingredients, such as glucose sirup, are temporarily stored in our tank systems, or tote systems, and then delivered through pumps.

The main mixing process takes place in the Slurry Prep Skid (also available from Shick Esteve), where ingredients are blended efficiently to ensure consistent quality and smooth processing.

Cooking

The cooking stage prepares gummy/jelly syrup with precision and consistency, accommodating various formulations from small batches to high-output production.

For sugar-free and specialty recipes, the Microfilm™ cooker offers vacuum thin-film technology for rapid, gentle cooking of heat-sensitive ingredients, while the Autofeed system efficiently weighs and mixes up to eight dry and liquid components with full batch control.

Other options include the Turbofilm™ continuous cooker, a compact unit combining syrup dissolving and cooking for high-output gummy lines, the Turbofilm™ mini cooker for small-scale or lab use, and the JellyCook™ batch cooker for accurate cooking of gelatin and pectin syrups.

To improve flavor and color, Addition Prep systems prepare small ingredients. This includes acids, colors, and active compounds. They ensure these ingredients are ready before use.

All systems are designed for hygienic operation, consistent quality, and seamless integration with depositing equipment.

Depositing

This step shapes and forms the gummies and jellies using starch-free moulds for superior hygiene and product variety.

- ServoForm™ gummy/jelly depositors are designed for efficiency, accuracy, and flexibility.

- ServoForm™ jelly is ideal for functional or medicated gummies/jellies requiring high validation.

- ServoForm™ mini supports small batch or lab-scale runs.

- ServoForm™ flexi provides adjustable setting times from minutes to hours, offering output up to 1,000 kg/hr.

CFA systems can be integrated for precise colour/flavour dosing minimizing waste and enabling rapid product changeovers.

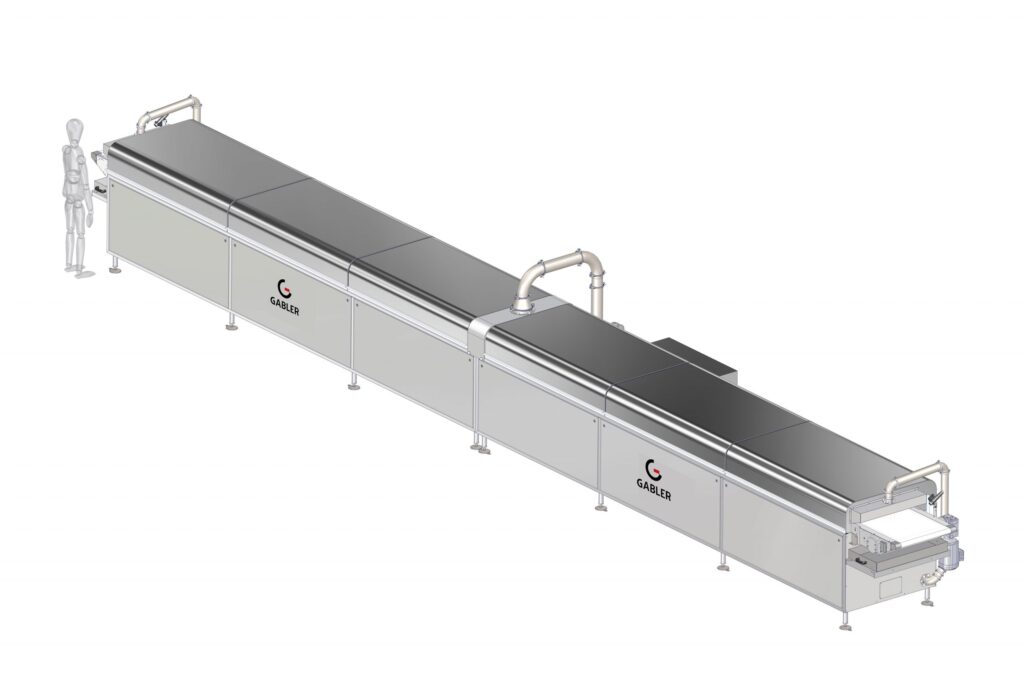

Cooling tunnel

Cooling & finishing

The final step in gummy and jelly production is cooling and finishing. Cooling tunnel cool the gummies to the right texture and firmness. They offer pre-cooling, intercooling, and final cooling options. These options fit different production needs and can handle up to 2,500 kg per hour.

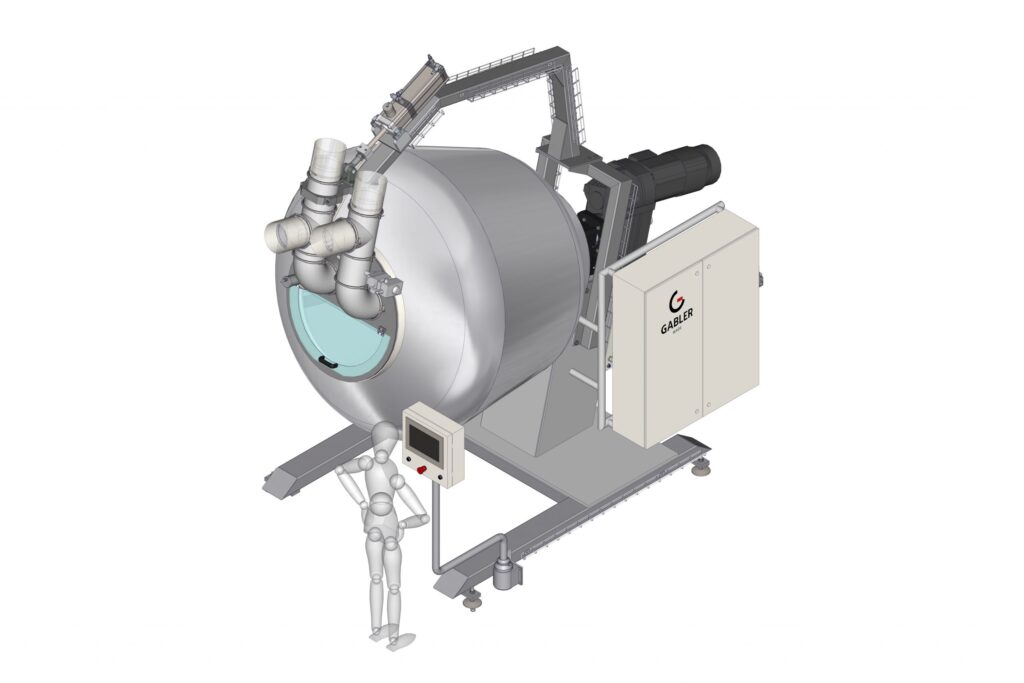

For finishing, automatic coating machines apply sugar, sour, or other flavor coatings evenly and quickly. These machines have precise spray control and recipe management. This ensures consistent quality and makes it easy to adjust for new gummy and jelly types or production sizes.

See our gummy and jelly production line in action

Discover how Coperion can enhance your gummy and jelly production

See Coperion’s starch free gummy/jelly production with a clean and precise process that boosts quality, speeds changeovers and enables innovative gummy and jelly varieties while ensuring hygiene and efficiency.

Related process technologies

Related applications

Get in touch

We take a distinctive approach to the processes that drive manufacturing. Let us know how we can help you achieve your goals for efficiency, productivity and safety.