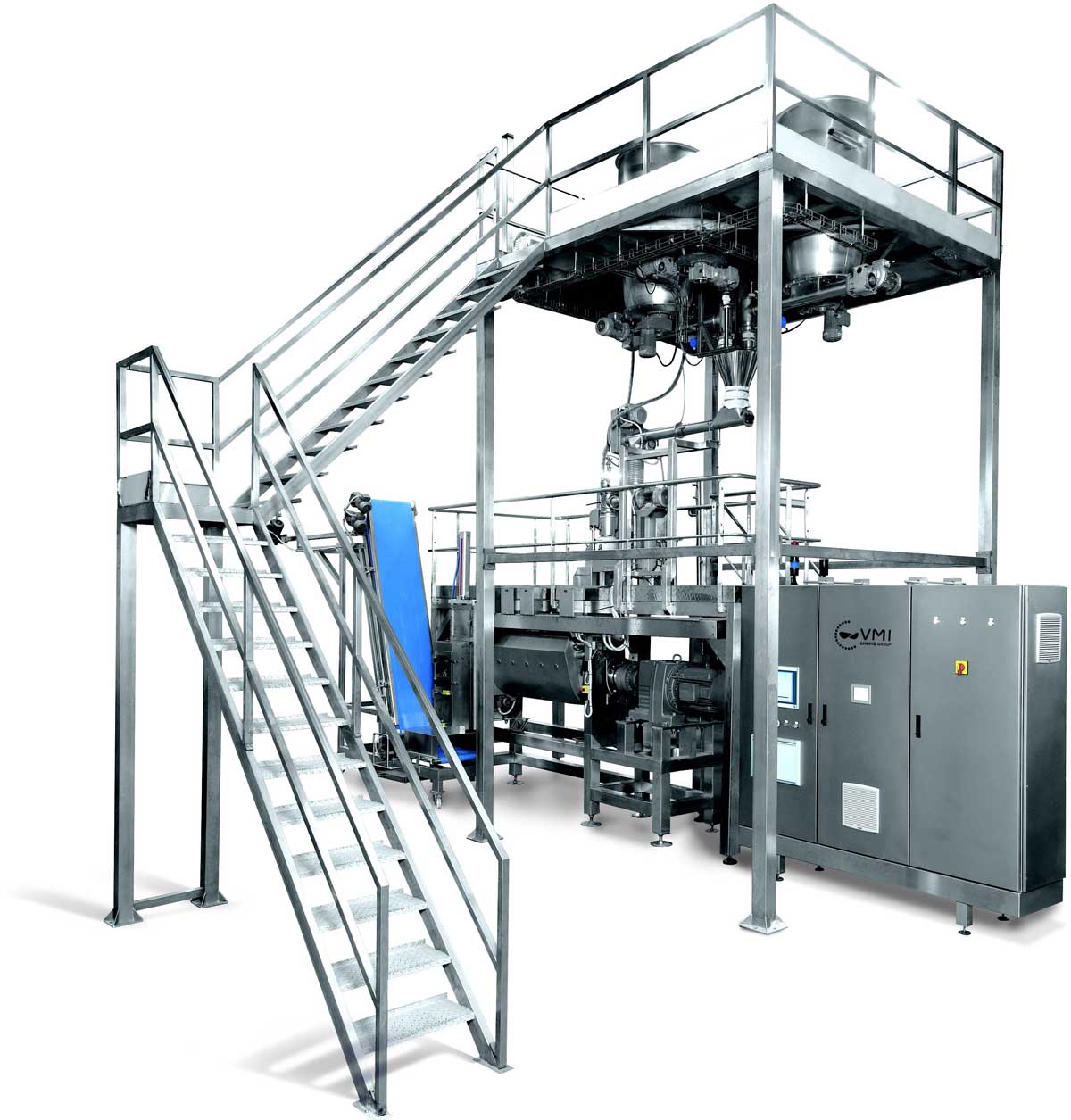

Continuous mixing of fresh, par-baked and frozen doughs

Backed by over 30 years of bakery expertise, the Verymix continuous mixer is built to deliver industrial bakeries reliable, high-quality dough and consistent 24/7 productivity, with a production capacity ranging from 500kg/hr to 8,000kg/hr.

Ideal for bakery cold supply chains

Thanks to its built-in cooling system, the Verymix provides an edge for industrial companies looking to produce consistent frozen dough applications, typically for baking at re-heating points. It excels at:

- Pre-proofed frozen dough

- Raw-frozen dough

- Par-baked dough

- Frozen dough

Typical end product applications produced with the Verymix system include breads like baguettes, ciabatta, pizza bases, danish pastry and puff pastry.

See the Verymix mixer in action

From dosing, pre-mixing, mixing, cooling, and scrap dough recovery, discover what makes the Verymix a truly innovative continuous dough mixer for modern industrial bakeries.

Alternatively, watch this on Youtube

Verymix continuous mixer specifications

- Temperature control and cooling

- Recipe and mixing parameters

- Hygienic design and food safety

- Controls and traceability

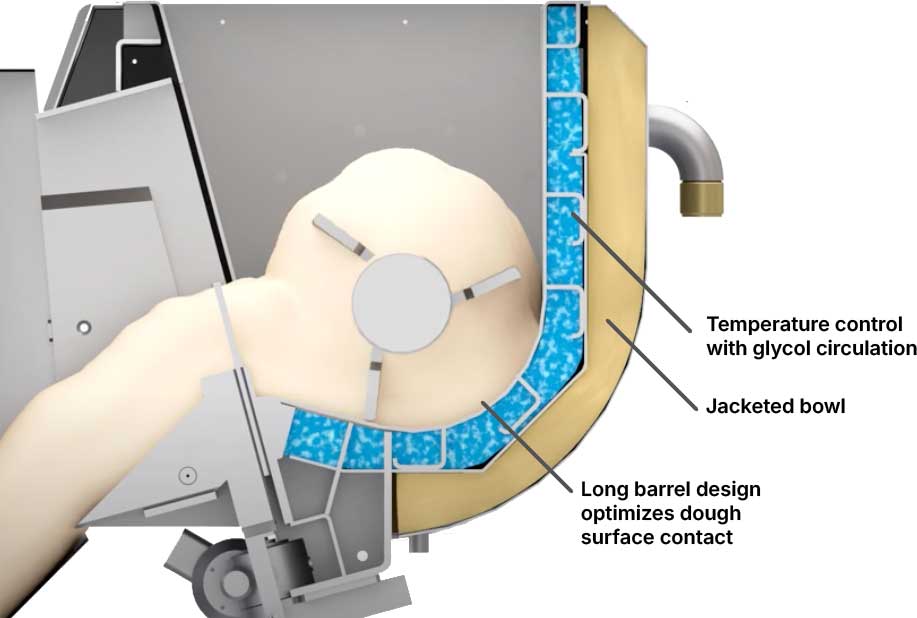

The Verymix continuous mixer features a double-jacketed, cooled mixing bowl that uses adjustable glycol water flow and temperature to precisely control dough temperature during mixing.

Its uniquely engineered bowl geometry enhances efficient heat exchange, ensuring optimal results for every dough type. This not only saves energy to your factory’s downstream processes but also helps to preserve your dough for future development steps.

Recommended output dough temperatures:

- Par-baked and frozen bread: 22 °C (72 °F)

- Raw frozen bread: 18–20 °C (64–68 °F)

- Frozen pastry: 16–18 °C (61–64 °F)

- Puff and Danish pastries: 13–14 °C (55–57 °F)

The Verymix continuous mixing system is designed to adapt to a variety of dough types and production methods. With fully adjustable parameters, it allows you to fine-tune the process to match your recipe and quality requirements.

Key recipe adjustable parameters include:

- Kneading rotors tailored to your dough type

- Adjustable mixing time and intensity

- Additional settings with the integrated horizontal pre-mixer, af VMI innovation that enhances consistency and hydration

Several continuous dosing units allow for total control over your recipe:

- Flour dosing

- Micro-ingredient dosing

- Powder dosing

- Cooled liquid & liquid dosing

- Scrap dough can be reinjected into the production and dosed accurately

Key hygienic features:

Designed for continuous 24/7 operation, the Verymix system meets the highest standards of hygiene and food safety.

- Smooth surfaces and and optimized drum design to minimize product retention and avoid product contamination.

- Option to install a CIP (Clean-in-place) system, subject to study.

The Verymix mixer features a state-of-the-art interface to perform recipe management and remain in control of your production at any time.

Key controls:

- A user-friendly recipe management interface where you can monitor consistency. Recipes can be generated by a MES and imported into the system.

- Monitor your dosing parameters and calibration in real time with a comprehensive view of the flow of the various dosing devices.

- Retain full traceability of the material used by production run. This consumption data can be exported to the MES.

Our experts says it better

“ The Verymix continuous mixer has been chosen by hundreds of industrial bakeries worldwide for its proven capacity to deliver high-quality frozen dough products with exceptional consistency and total traceability ”

– José Cheio de Oliveira, VMI’s R&D manager

Download

brochure

To learn more about the Verymix continuous mixer system, please download our PDF documentation.

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.