Cone mill KEK

Intermediate mills and granulators

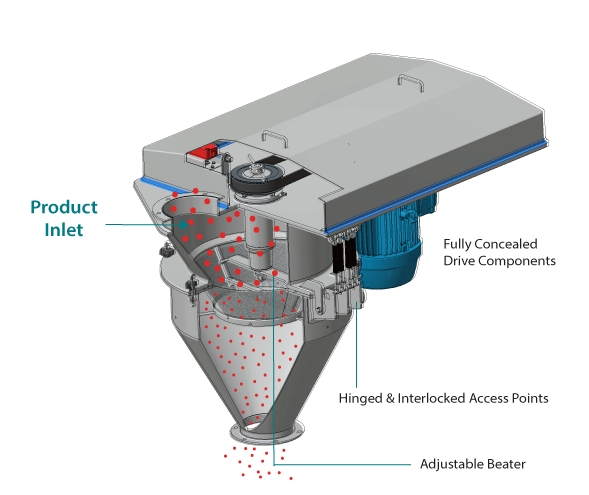

The KEK cone mill from Kemutec is a high-performance vertical milling machine engineered for versatile, high-speed size reduction. Designed for food and pharmaceutical processing, the cone mill delivers uniform and consistent particle sizes across a wide range of materials.

The milling is globally recognized as one of the most versatile size reduction milling machines, due to the wide range of materials it processes. The KEK range includes the widest available, from lab through to bulk production and are widely used in the food processing industries, as well as pharmaceutical processing.

KEK Cone Mills have the ability to take a wide range of feed material and produce an equally wide range of product, making this milling machine ideal for intermediate sizing in both wet and dry granulation. For maximum process versatility, it also includes variable speed control.

See the KEK mill in action

Watch the KEK milling machine in action — a high-speed, versatile milling machine for uniform sizing in food and pharma processing. Ideal for both wet and dry granulation with full process control.

Alternatively, watch this video on Youtube.

- Overview

- Design Options

- Gallery

The KEK cone mill gently mills and grinds material at controlled high speeds to achieve uniform particle size distribution. With the widest range of models available from lab-scale units to full production systems, the KEK cone mill supports both wet and dry granulation, making it ideal for intermediate sizing applications.

Thanks to its variable speed control, the mill offers precise process adjustment for handling materials from 4 mm down to <250 micron, including heat-sensitive, moist, or fatty products.

- Grinds material into a uniform size, ensuring consistent quality control

- Versatile performance to mill and grind a wide variety of materials

- Ideal even for fatty, heat sensitive and moist products

- Variable particle size ranging from D50 – 500μ to < 250μ

- High efficiency operation, gentle grinding motion

- Low dust; reducing air filtration installation costs

- Low noise; benefiting the operator

- Low levels of heat generation – essential for when milling heat sensitive products

- Variable speed drive, for even greater control

- Multiple drive configurations, providing higher flexibility

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.