Cakes, desserts & baked fillings applications

Cheesecakes manufacturing technologies

Coperion technologies provide seamless, scalable solutions for producing formed-crumb base cheesecakes with precision and consistency. Our integrated systems are designed for high-output operations, delivering flexibility, hygiene, and long-term performance for global manufacturers.

Scalable solutions for cheesecake production

Cheesecake production demands precise control over ingredient handling, mixing, depositing, and finishing to achieve consistent texture, structure, and visual appeal.

Coperion offers integrated lines for:

- Oven-baked cheesecakes

- No-bake cheesecakes

Whether producing baked or no-bake cheesecakes, manufacturers must manage sensitive dairy ingredients, high-viscosity batters, and delicate crust structures with accuracy and hygiene.

Coperion helps industrial and premium cheesecake manufacturers with integrated processing technologies designed for scalability, repeatability, and top-quality products at every stage.

How industrial cheesecake production works

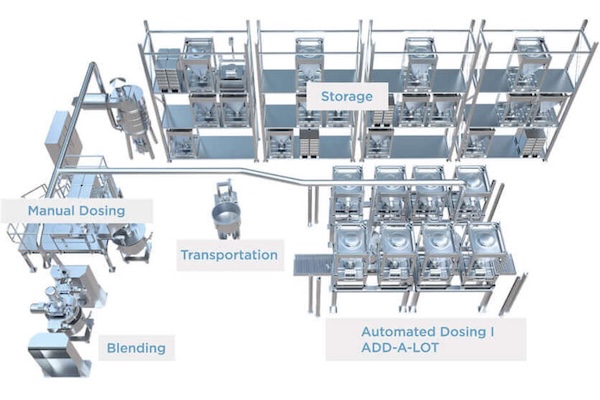

Ingredient handling

For solid ingredients such as flour, sugar, and crumbs, Coperion provides unloading solutions, including bag dump stations, for efficient handling and storage.

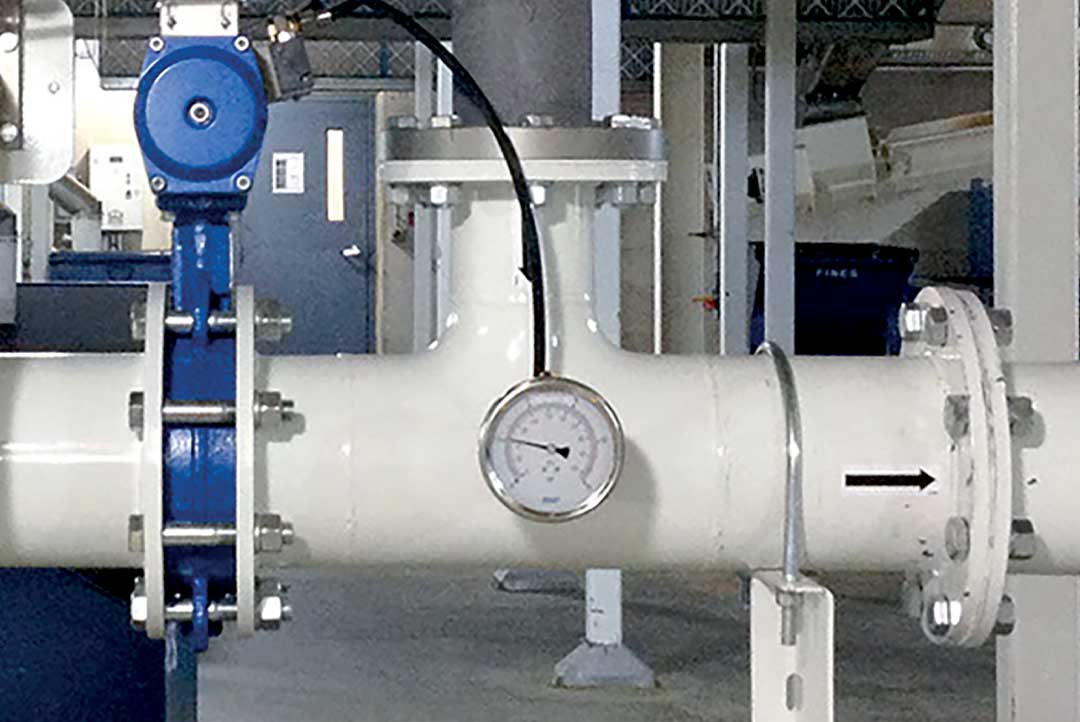

Flour can be stored in Schick Esteve silos and routed through the production line using sanitary valves and pneumatic conveying systems.

Liquid ingredients like oils, glucose syrup and water are stored in tanks, totes thanks to our IBC tote system

All systems are designed for food safety, traceability, and seamless integration with downstream dosing and mixing equipment.

Cheesecake batter mixing

Cheesecake batter is then prepared in planetary batter and cream mixers, which provide gentle but thorough mixing to achieve a smooth, uniform texture without over-aeration, ensuring consistent batter quality for depositing. Please consult us for the best mixer recommendation for your recipe and production volume.

Batter transfer from mixing bowl to production line

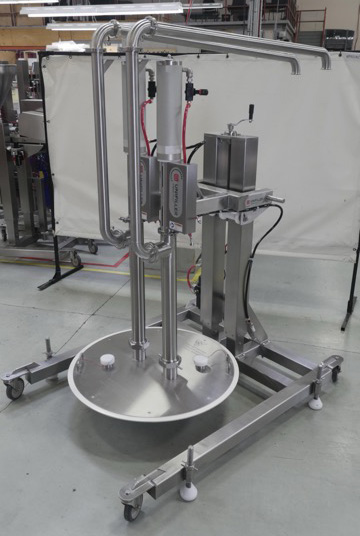

Once the cheesecake batter achieves the required consistency, it can easily be pumped out from the mixer bowl and delivered to the next stage’s production line thanks to our Hopper Topper.

Hopper Toppers significantly reduce musculoskeletal strain for bakery workers and help lower the risk of work-related disorders. In recognition of this contribution, our hoppers received the 2024 MSD Design Award (UK).

For higher throughput, the Dual Hopper Topper Max by Unifiller is also available. It is designed to pump cheesecake batter to feed up to two depositor hoppers simultaneously.

The pumping system can be fitted with an optional “follower-plate”, which increases suction and eliminates the need for manual assistance with a paddle to push batter toward the pump inlet. The follower plate also acts as a cover over the batter, helping to prevent contamination.

Option 1 – Integrated pre-baked cheesecake line

An integrated cheesecake line from Unifiller automates assembly:

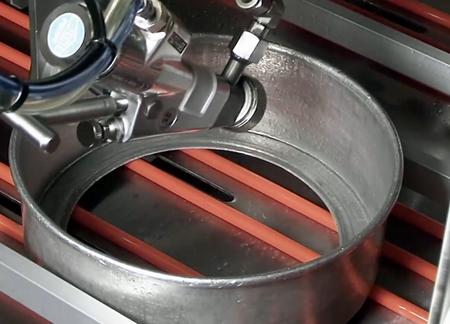

- pan preparation and oil spraying

- dosing and feeding of the crumbs to create the bottom later

- tamping to create a homogeneous layer

- cheesecake batter depositing

- optional marbling process can take place before the baking stage

For more information about our integrated pre-bake line, please see our video.

For producers looking to complement an existing line, individual machines are also available:

- pan preparation with release agent spraying systems

- ingredient depositing with bakery depositors

Following batter depositing (and optional marbling), cheesecakes are sent to the baking station or passed through a tunnel oven.

Option 2 – Integrated chilled set cheesecake lines

For no-bake cheese cakes, Unifiller also supplies integrated chilled set cheesecake lines.

The process usually consists of:

- crumb depositing

- cheesecake batter automated depositing

- optional filling layers (eg. jam) can be also automated

Integrated finishing & decorating lines

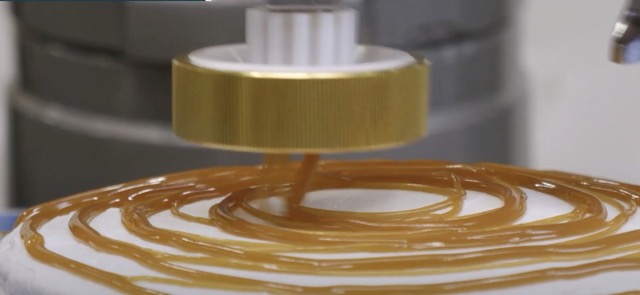

For large capacity producers, the finishing and decorating process is integrated in our cheesecake lines. During the finishing process, the line will spin the cheesecakes and add:

- Glazing

- Jelly or fruit depositing

- Sauce and coulis

- Pipe cream rosettes

Individual stations for finishing & decorating

Individual stations are also available by Unifiller for the finishing and decoration of cheesecakes:

- CakeStation by Unifiller, an all-in-one station to accelerate cake decoration like rosettes and borders.

- HIRO robot by Unifiller, a smart writing, drizzling, and custom cake decoration

Slicing & cutting

For bakeries looking to further portion their cheesecakes, the slicing of the cheesecakes can be automated and processed in line after the cheesecakes have been chilled. Inline ultrasonic slicers by Bakon will achieve clean precise cuts, ensuring consistent slice weight, shape, and visual quality.

See our pre-bake cheesecake line in action

From pan oiling and base crumbing to batter depositing and marbling, this cheesecake integrated line does it all. Ideal for industrial bakery plants and large commercial bakeries

Alternatively, watch this on Youtube

Related process technologies

Related cake, desserts & baked fillings applications

Get in touch

We take a distinctive approach to the processes that drive manufacturing. Let us know how we can help you achieve your goals for efficiency, productivity and safety.