KEK sifter

Industrial screening and deagglomeration

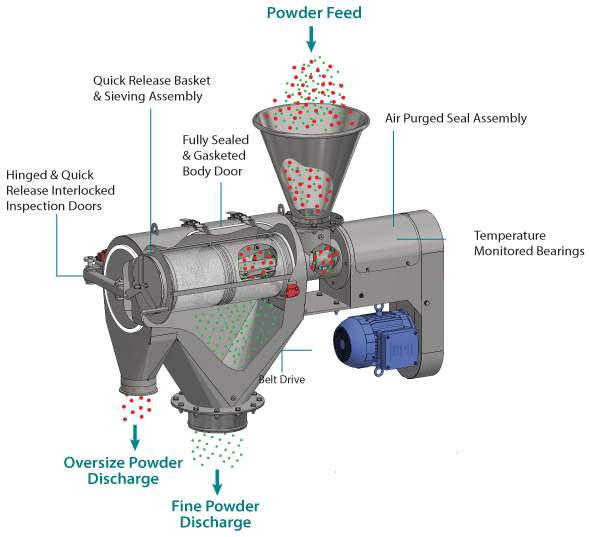

The KEK sifter from Kemutec is a high-capacity industrial centrifugal screening machine. This KEK sifter is designed for precise powder classification and contaminant removal, making it widely used in food and pharmaceutical production.

As a result, it ensures consistent particle size, reliable throughput, and hygienic operation for demanding environments.

See KEK sifter in action

Discover how the KEK sifter improves powder handling efficiency. In addition, it reduces waste and supports hygienic operation for food and pharmaceutical manufacturers. It also minimizes downtime due to easy cleaning and maintenance.

Alternatively, watch this video on Youtube.

- Overview

- Range

- Benefits

- Features

- Gallery

High-capacity powder screening

Sifting material with the KEK sifter not only classifies particle size but also removes unwanted material. Consequently, it reduces risks in powder handling and ensures consistent product quality.

Accurate size classification and contaminant removal

Sifting material with the KEK sifter not only classifies particle size but also removes unwanted material. As a result, it reduces risks in powder handling and ensures consistent product quality.

Versatile KEK sifter applications and alternative names

Also known as a rotary sifter, flour sifter, or powder sifter, this machine supports a wide range of applications. For example, it works in both gravity and inline systems, with capacities ranging from a few pounds per hour to over 90 tons per hour. In addition, it can handle a variety of materials, from fine powders to granular products.

| Design | Model size | Screen area | Motor hp |

|---|---|---|---|

| Cantilever shaft design | Lab sifter | 0.044 m² | 0.5 |

| Cantilever shaft design | Mini sifter | 0.044 m² | 0.5 |

| Cantilever shaft design | K300C | 0.084 m² | 0.75 |

| Cantilever shaft design | K650C | 0.332 m² | 3 |

| Cantilever shaft design | K800C | 0.576 m² | 5 |

| Cantilever shaft design | K1150C | 1.096 m² | 10 |

| Non-cantilevered shaft design | K1350C | 1.317 m² | 10 |

Plus, this range ensures that the KEK sifter can be adapted for small-scale to large-scale operations. Meanwhile, operators benefit from faster setup and minimal downtime.

- Provides size classification of material by sifting and also separating out material that isn’t to the required size

- Screens material to remove unwanted material and de-risk from contamination

- Enables high-efficiency, high-speed performance

- Quick and easy to clean, with hygienic cantilever design

- New paddle assembly design to provide and even more hygienic view

- Cantilever shaft also ensures no oversize bearing or seal

- 30 second screen changes, via easily removable sifter screen for inspection and cleaning

- Additional easier inspection, cleaning and maintenance, due to oversized end door

- Operator friendly – no tools typically required for stripping down and cleaning

- Models that can process from a few kilograms per hour, to over 90 tons

- Gravity and inline pneumatic conveying designs

- 7 model sizes in range

The KEK centrifugal sifter provides a safer, cleaner, and more productive solution compared to traditional flat-deck powder sieves. It then enhances operational efficiency while minimizing dust, noise, and vibration.

| Feature | Horizontal flat deck powder sieve | Centrifugal sieve |

| Efficiency | High residency time | High efficiency and lower residency time |

| Speed | Slower processing | Faster processing |

| Levels | Several levels of separation | Single level of separation |

| Dust generation | Generates more dust Airborne particles due to movement | Generates less dust Enclosed operation, and less air displacement |

| Capacity | Lower capacity rates per screen area | Higher capacity rates per screen area |

| Vibration level | Vibrate / tumble | Low vibration / static |

| Noise | Noisy (approx. 75 db(A)) | Low noise levels |

| Connections requirement | Requires flexible connections | Compatible with both static/ flexible connections |

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.