Candy applications

Fondant & fudge manufacturing technology

Coperion offers fully integrated fondant and fudge production systems designed to deliver precise dosing, fast changeovers, and hygienic processing. Our advanced technology ensures consistent quality and efficiency for hard candies used in food, health, and pharmaceutical industries.

Starch-free solutions for fondant & fudge production

Fondant and fudge, including varieties such as plain, flavoured, layered, and enrobed products, are produced efficiently using advanced cooking, depositing, and forming technology, the industry-standard method for high-quality confectionery.

Coperion’s advanced equipment ensures precise control over candy size, shape, colour, and flavour, supporting both traditional and innovative recipes.

From classic solid pieces to enrobed designs, our integrated lines provide consistent quality and smooth scalability from lab trials to full production. For enhanced product appeal, fondant and fudge can be produced in enrobed, layered, or flavoured varieties, delivering consistent texture, colour, and flavour across all formats.

Examples of innovative fondant & fudge applications

Bring to the market a new generation of exciting fondant and fudge. From plain to flavoured, layered or enrobed, our versatile concepts are crafted to delight today’s confectionery fans. And with recipe and process support from our global Test Center teams, we help turn every idea into sweet reality.

Base

Fondant for confectioners

Enrobed

Fondant crèmes

Enrobed

Soft fondant

Chocolate-panned

Small toffees & fondant

Enrobed

Fruit cordials

Enrobed

Caramelised fondant

Enrobed

Fudge

Enrobed

Fondant bars

Enrobed

Milk fondant

How fondant & fudge production works

(MIH systems)

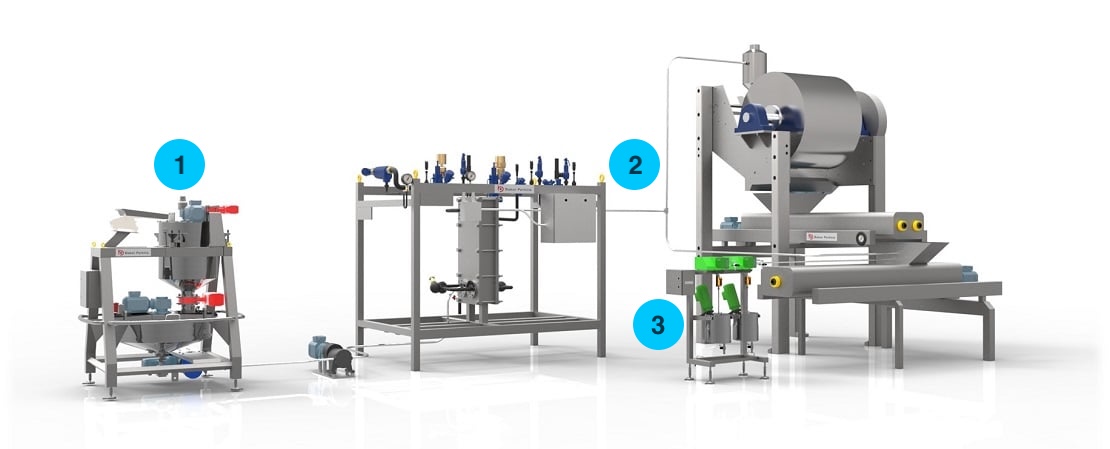

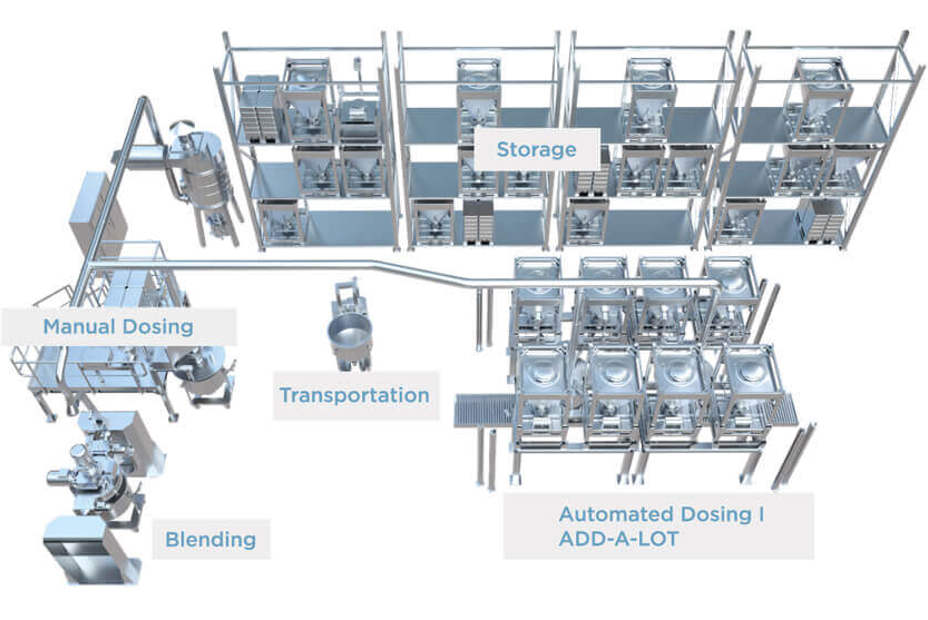

Ingredient handling

Multi-Ingredient Handling (MIH systems)

Bag dump stations provide a safe, dust-free way to manually add dry ingredients such as sugar, while liquid ingredients like glucose syrup and water are stored in tanks or totes and delivered through pumps. These systems ensure safe handling and consistent delivery of raw materials for precise weighing and mixing.

Cooking

The cooking and beating stage transforms raw ingredients into a precise fondant or fondant crème with the correct texture, moisture, and consistency. This step ensures smooth, creamy products with uniform flavour and quality.

For delicate or specialty recipes, the Microfilm™ cooker uses vacuum thin-film technology for gentle, rapid cooking of heat-sensitive ingredients, while the Autofeed system accurately handles multiple dry and liquid components with full batch control.

Optional Carablend™ cooker is available for recipes requiring precise control over colour, flavour, or moisture before beating.

All systems are designed for hygienic operation, consistent quality, and seamless integration with downstream depositing or forming equipment.

Depositing

Fondants and fudges are portioned using a ServoForm™ soft confectionery depositor, designed to handle viscous, creamy products without compromising texture. The depositor produces uniform pieces in the correct weight and size, maintaining smooth surfaces and consistent quality.

Products handled can include plain, flavoured, layered, enrobed, or fondant crème varieties. Integrated systems allow for flexible product shapes and designs while maintaining hygienic, high-speed production.

CFA Systems can be integrated for precise colour/flavour dosing minimizing waste and enabling rapid product changeovers.

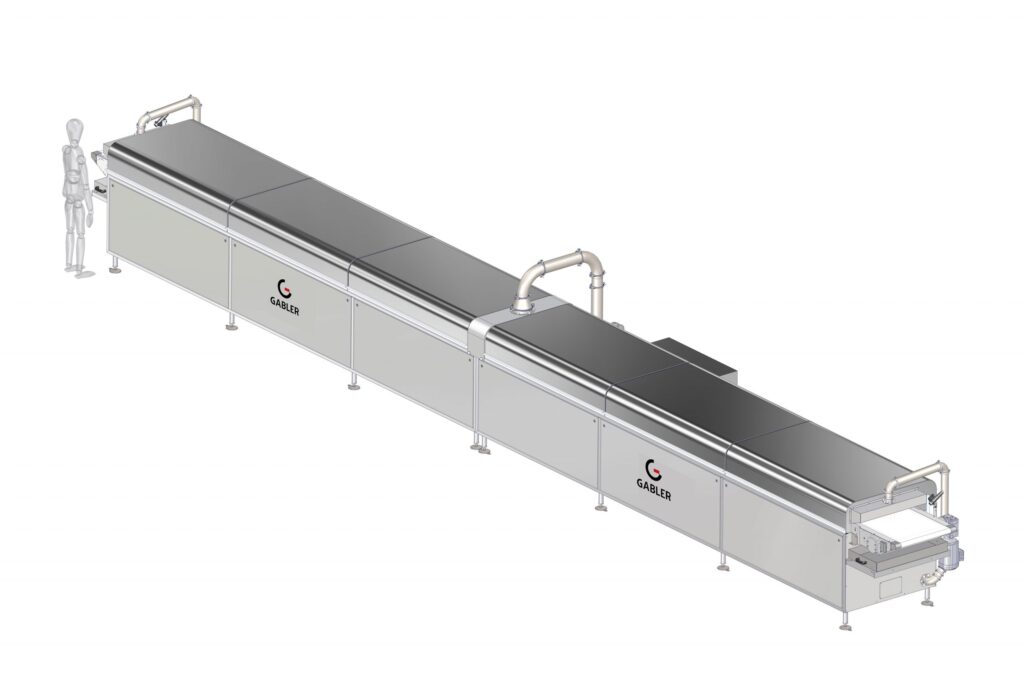

Cooling tunnel

Cooling & finishing

The final step in fondant & fudge production is cooling and finishing. Cooling tunnel lowers the temperature of freshly deposited fondant & fudge, ensuring they set with the correct hardness, glossy surface, and stable shape.

Optional finishing equipment includes enrobing, glazing, or wrapping systems, preparing products for packaging. These systems are designed for hygienic, efficient, and high-speed operation while minimizing manual handling.

Related process technologies

Related confectionery applications

Get in touch

We take a distinctive approach to the processes that drive manufacturing. Let us know how we can help you achieve your goals for efficiency, productivity and safety.