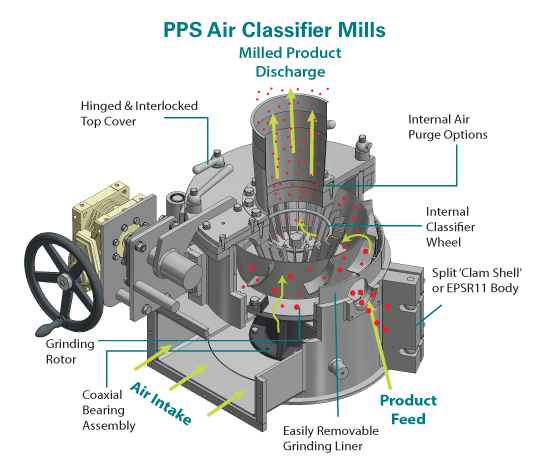

Air classifier mill PPS

for heat-sensitive and specialty powders

Kemutec‘s PPS air classifier mill is ideally suited for grinding ultra-fine powders, as well as heat sensitive powders. This type of air classifying milling machine is widely used in the food, nutraceutical, and pharmaceutical industries.

Moreover, precise control over the “particle cut point” is achieved through an internal air-classifying wheel and an independent drive, while typical milled particle sizes reach a D50 as low as 5 to 10 µm.

Consequently, these mills produce ultra-fine, consistent powders with minimal heat generation. For example, they are ideal for spices, grains and gluten-free flours, sugar refining, cocoa processing, plant-based proteins, nutraceuticals, and botanical ingredients. As a result, their precise classification ensures superior product quality, improved flavor retention, and reliable particle-size control for demanding food applications.

See PPS mill in action

See the Kemutec PPS mill in action, efficiently grinding heat-sensitive and specialty powders for food, pharmaceutical, chemical, and coating applications. Precise, easy to maintain, and built for consistent quality.

Alternatively, watch this video on Youtube.

- Overview

- Options

- Gallery

PPS air classifying machines are ideal for ultra-fine and controlled particle size grinding

Kemutec’s mills includes an gas intake system for either air or inert gases, while its grinding media parts are interchangeable – providing easy maintenance.

To allow for simple and quick access the mill also features a hinged and interlocked top cover. Its performance is extremely efficient, making the PPS mill a popular choice for fine powder processors.

Design options

- High energy controlled grinding

- Temperature controlled grinding

- Tight particle size distribution

- Easy to clean with unique side opening design

- Easy to adjust particle size output

- Integral classifier for a fine powder

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.