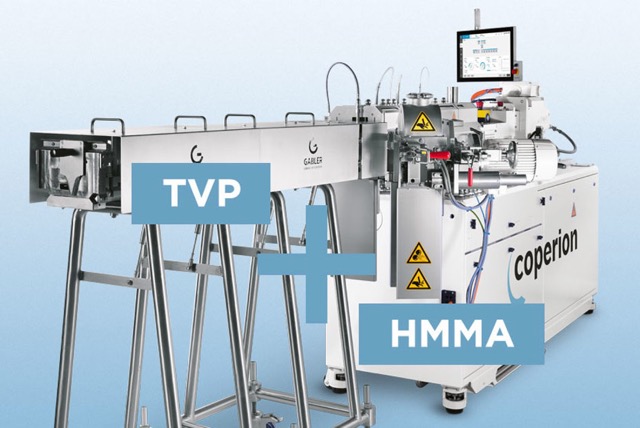

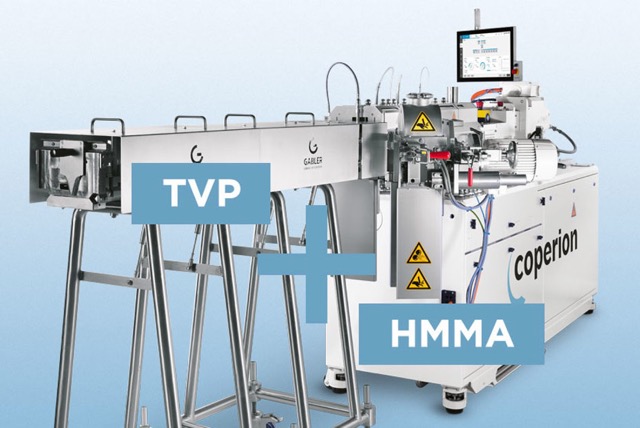

ZSK food extruder in hybrid version

Hybrid food extruder for alternative proteins

Rapid switching between TVP and HMMA

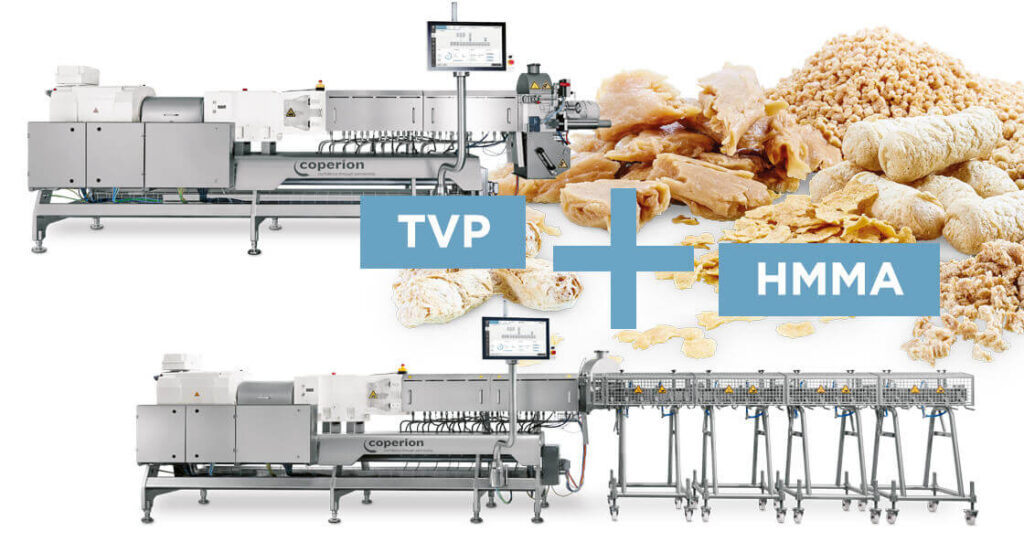

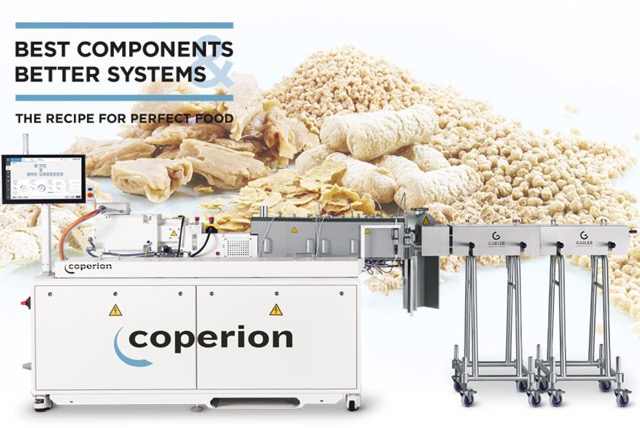

The ZSK food extruder in hybrid version from Coperion enables flexible, efficient production of both TVP and HMMA on a single line. Its quick-change design and self-cleaning screws allow fast product conversion, making it ideal for small to mid-scale operations, research units, and start-ups entering the plant-based protein market.

Ideal applications:

- Texturised Vegetable Protein (TVP)

- High Moisture Meat Analogue (HMMA)

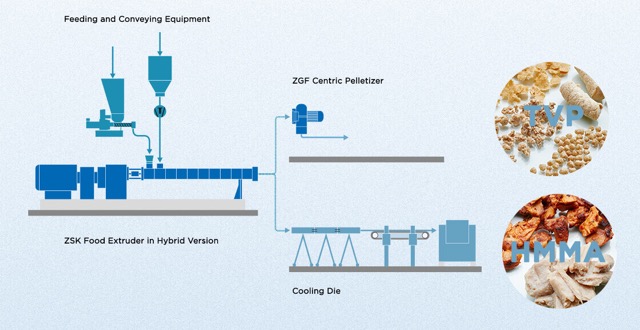

The ZSK food extruder in hybrid version, together with the MEGAtex cooling die, forms the core of the high moisture extrusion process.

Coperion’s ZSK food extruder in hybrid version allows flexible changes between TVP and HMMA production

- Overview

- Gallery

- Resources

ZSK food extruder hybrid version delivers flexible production of plant-based proteins, enabling manufacturers to produce both TVP and HMMA on a single line while maintaining product quality and process efficiency. Its self-cleaning twin screws, rapid changeover design, and modular discharge options allow quick adaptation between product types, minimizing downtime and simplifying operations.

Quick conversion from TVP to HMMA

With its adapter system, operators can switch between a ZGF centric pelletizer for TVP and a MEGAtex cooling die for HMMA in just one to two hours without the need for an electrician. The process section remains unchanged, and the self-wiping screws prevent material buildup, ensuring safe, hygienic production and fast product conversion.

Ideal for small to mid-scale operations and innovation

The ZSK food extruder in hybrid version is ideal for start-ups, research units, and mid-scale manufacturers entering the growing plant-based protein market. It allows efficient production of both dry, shelf-stable TVP and high-moisture, meat-like HMMA with minimal investment, offering a versatile, future-ready solution for evolving market demands.

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.