Valves

Valves for food, health, and pharmaceutical industries

An extensive range of hygienic valves for the food & pharmaceutical industries

Coperion and its technology brands provide one of the most advanced ranges of valves for the food industry, designed to meet the strict requirements of food, pharmaceutical, and nutraceutical processing. These hygienic valves feature robust construction, smooth product-contact surfaces, and easy-to-clean configurations. As a result, with their hygienic design, the valves support stringent standards.

In addition, these valves are also compatible with plastics, chemicals, and mineral processing applications. For more details, please visit the valve page on Coperion performance material website.

Conveying valves for food industry

Valves for conveying applications mainly control pneumatic flows in food, pharmaceutical, and nutraceutical processes. They also help ensure smooth product transport and reduce contamination risks. For example, they keep materials moving efficiently between mixers, silos, and packaging lines.

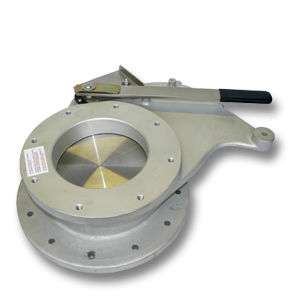

Butterfly

valves

Butterfly valves employ a flat, rotating disc mounted on a central shaft to open or close flow. This mechanism provides quick, reliable shut-off as well as basic throttling, making it ideal for liquids, slurries, and air conveying. Moreover, their lightweight design combined with sanitary construction allows for easy cleaning and efficient operation.

Diverter

valves

Diverter valves route dry bulk materials, such as powders, grains, or pellets from a single source line to multiple destination lines. Then, an internal flap, rotor, or sliding blade switches paths efficiently. This allows product to go to mixers, packaging lines, or storage bins while keeping hygienic standards.

Rotary

valves

Rotary valves have a rotating, pocketed rotor inside a tight housing to meter dry bulk materials like flour, sugar, starch, or grains from one process step to another. They also maintain an airlock between zones, feed pneumatic lines steadily, and prevent air pressure loss. So, these valves are essential for precise process control in high-capacity systems.

Gravity flow control valves for food industry

Valves in this category not only manage the free-fall flow of materials under silos or hoppers, but they also ensure safe, smooth, and hygienic handling in high-capacity systems. Besides, they help prevent blockages and material buildup.

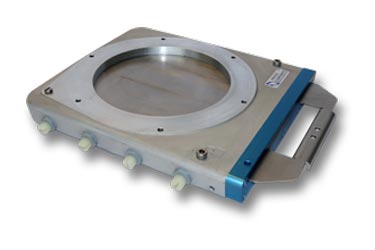

Disc gate

valves

Disc gate valves use a flat sliding plate to open or fully block the flow of dry bulk materials. Because they are simple and reliable, they also minimize product shear. This makes them suitable for isolating hoppers, bins, and feeders.

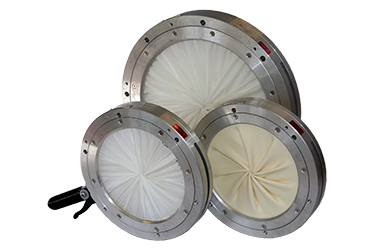

Iris diaphragm

valves

Iris diaphragm valves consist of overlapping “leaves” that open and close like a camera aperture, creating a concentric, variable opening. They are also very useful for gently regulating powders, grains, pellets, and other fragile bulk solids.

Slide gate

valves

Slide gate valves provide controlled isolation of hoppers and feeders. The sliding plate mechanism allows precise flow control with minimal product stress. Then, they become ideal for high-capacity dry bulk applications.

Other valve types

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.