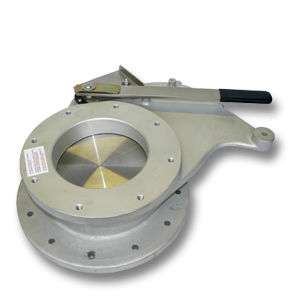

Disc gate valves

Disc gate valve component

for food and pharmaceutical industries

About our disc gate valves

Coperion offers a complete range of disc gate valve components that isolate and control the discharge of powders, granules, and sensitive bulk materials. Each valve uses an innovative disc mechanism that delivers reliable performance, minimises product retention, and meets strict hygiene standards. Because of these benefits, the valves are well suited for food and pharmaceutical processing.

What are disc gate valve components for?

Disc gate valve components help operators stop, divert, or release materials in a controlled way. They are often installed beneath silos, hoppers, and transfer points to keep product flow stable. In addition, their hygienic design reduces the risk of contamination during handling. As a result, processing lines that work with powders, granules, or delicate bulk products can maintain secure and consistent flow control.

Features:

- Smooth, hygienic surfaces that help prevent contamination

- Reliable material isolation for accurate and stable batch control

- Wear-resistant construction for long-term use with abrasive powders and granules

- Tight sealing to reduce leakage and dust emissions

- Compact, space-saving design for greater layout flexibility

- Easy access for cleaning and maintenance, thereby reducing downtime

Coperion disc gate valves don’t only support safe, efficient, and hygienic material handling, but it’s also making them a trusted choice for manufacturers in food and pharmaceutical sectors.

Choosing the right disc gate valves for your needs

Several factors influence valve selection, including material type, flow behaviour, hygiene requirements, and expected wear. Selecting the right design ensures good sealing performance, straightforward cleaning, and reliable handling of powders and granules. For example, food and pharmaceutical processes often need stainless-steel surfaces and food-grade seals. Meanwhile, abrasive materials may require a heavier-duty or reinforced design to extend service life.

In addition, for other types of flow control valves for food & pharma industries, see our valve range here.

Valve ranges are also available for plastics, chemical, and mineral processing applications. For more details, please visit the valves page on the performance materials Coperion website.

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.

Interested about this topic?

Follow Coperion’s Food Health & Nutrition social media channels to receive updates and videos about our latest technologies and product applications.

>> LinkedIn

>> Youtube

>> Instagram