success stories

Starch-free depositing increases capacity and creates opportunities in the healthcare market

Share

Healthcare-ready starch-free depositing boosts product quality

Healthcare growth is accelerating demand for precise, hygienic, starch-free depositing. When Indian confectionery manufacturer MALA’S needed to scale production of their 3D jellies and expand into healthcare applications, they turned to Baker Perkins, a Coperion technology brand. Their two low-output depositors could no longer support rising demand, prompting a move toward a high-capacity, healthcare-ready starch-free solution.

Longstanding expertise and innovative technology enable tailored solutions

MALA’S is a 60-year-old family-owned company near Pune, Maharashtra, specialising in processed fruit products including jams, mocktails, syrups, sauces, and honey. Their flagship product is a strawberry-shaped soft pectin jelly made with local fruit and sugar.

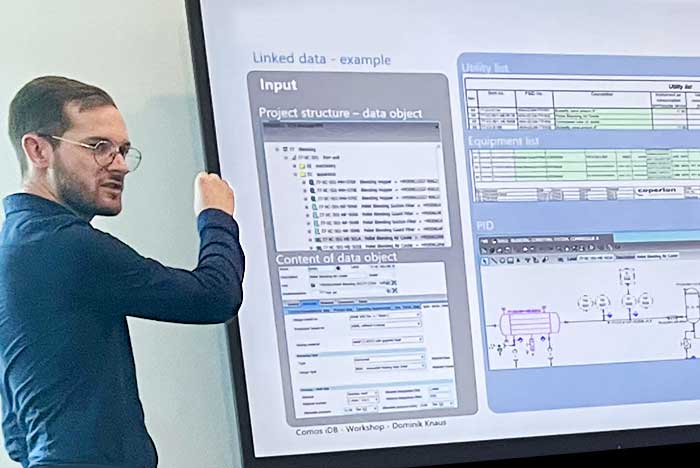

After contacting Baker Perkins’ Indian agent, 3P Solutions, and conducting trials at the Baker Perkins Innovation Centre in Peterborough, it became clear that a single high-output line would not only meet MALA’S production needs but also improve product quality, line efficiency, and reliability.

Custom-built starch-free line for increased capacity and flexibility

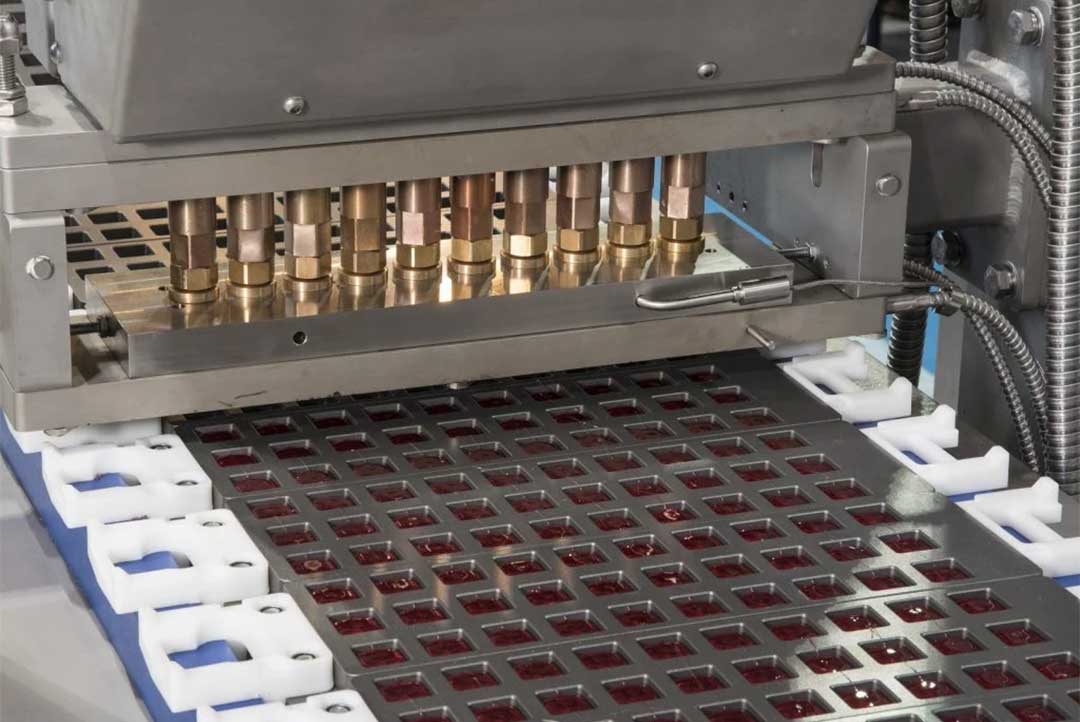

The newly commissioned 850 kg/hour Microfilm™ cooking and ServoForm™ depositing line delivers more capacity than the previous two depositors combined. It also allows greater product flexibility: carrageenan can be added for firmer textures, and fruit pastes are easily handled.

Moulds are quickly interchangeable, enabling production of both 3D and 2D jellies. The 3D strawberry jellies now exhibit significantly improved definition and consistency, reflecting the precision and reputation of the ServoForm™ depositor.

Expansion in the healthcare sector

The line’s starch-free depositing process delivers consistent size, weight, and appearance in a fully hygienic environment. This has facilitated MALA’S entry into the healthcare market, producing jellies fortified with vitamins, Omega-3, minerals, fiber, protein, and energy supplements, a rapidly growing sector.

Depositing also allows for multiple production formats: one or two colours, stripes and layers, soft or solid centre-fills, and inclusions such as real fruit pieces. Unlike traditional starch moulding systems, it supports intricate 3D shapes and simultaneous production of multiple product varieties, all with lower capital and operating costs compared with starch moguls, die forming, or cut-and-wrap methods.

Delivering quality, flexibility, and market growth

Starch-free depositing is increasingly the process of choice for confectioners seeking original, high-quality jellies. For MALA’S, the Baker Perkins solution has not only increased output and product consistency but also created new opportunities in the high-value healthcare sector, positioning them for continued growth.

Related solutions

Stay connected

Subscribe to keep up to date with current perspectives, events, white papers and more.