Biscuits, Cookies & Crackers applications

Soft dough biscuits manufacturing technologies

Coperion’s soft dough biscuit technologies provide seamless, scalable solutions for producing moulded biscuits with precision and consistency. Our integrated systems are designed for high-output operations, delivering flexibility, hygiene, and long-term performance for global manufacturers.

Scalable solutions for soft dough biscuit production

Soft dough biscuits, including varieties such as 3D moulded biscuits, chocolate fingers, digestive biscuits, moulded shortbread, and soft oat biscuits, are produced globally using rotary moulding, the industry-standard method for soft dough.

Coperion’s advanced equipment ensures precise control over biscuit size, shape, weight, thickness, and surface design, supporting both traditional and innovative recipes.

From simple, classic biscuits to decorated or enrobed treats, our integrated lines provide consistent quality and smooth scalability from lab trials to full production. For enhanced product appeal, biscuits can be partially or fully coated with chocolate, or incorporate inclusions like oats, nuts, and fruits.

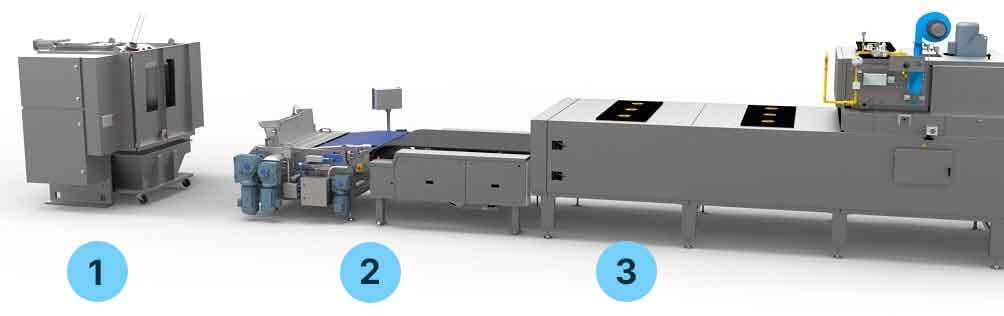

How soft dough biscuit production works

Mixing & dough feed

Production begins in the mixer, where ingredients are blended into a uniform dough. Coperion integrates a range of mixers from leading partners, giving manufacturers flexibility to choose the best fit for their soft dough process:

- High-speed mixer – from Baker Perkins

Designed for rapid dispersion, the shaftless mixing blade ensures thorough incorporation of inclusions such as oats, nuts, or chocolate pieces without damage. Batch capacities range from 650–1,300 kg for soft dough applications. - KleanVue® open frame mixer – from Peerless

A triple-action horizontal mixer with an open-frame sanitary design. Ideal for doughs with inclusions, it offers excellent hygiene and accessibility for fast, reliable cleaning and frequent changeovers. - High-duty horizontal sigma arm mixers – from Shaffer

Designed for dense or sticky doughs, these mixers deliver consistent and reliable performance. For inclusion-heavy recipes, optional horizontal Sigma Arm configurations provide gentle yet thorough mixing with precise ingredient distribution. Batch sizes range from 600–2,450 kg, depending on the model. - Pioneer medium-duty mixer with sigma arm agitator – from Peerless

A versatile solution capable of processing both soft and hard doughs. Fitted with a Sigma arm agitator, it combines robust dough handling with efficient mixing, making it well-suited for inclusion-rich or higher-viscosity doughs while ensuring consistent batch quality. - Vertical mixers – from VMI

Offering gentle dough development, VMI’s vertical solutions include fork mixers that maintain dough extensibility and spiral mixers that provide efficient kneading with precise control.

Once mixed, the dough is discharged into the dough feed system, ready to be formed.

Shaping & moulding

The dough moves to the rotary moulder, which shapes each biscuit and applies surface designs. The machine:

- Sets precise size, weight, thickness, and shape.

- Can add lettering, intricate patterns, or 3D images.

- Supports trial runs in the laboratory rotary moulder before full production for rapid product development.

Rotary moulding ensures each biscuit is consistent in appearance and quality, whether producing standard biscuits or decorative 3D shapes.

Baking & handling

Shaped biscuits enter the TruBake™ convection oven, where jets of hot air from plenum chambers above and below the belt provide even baking.

- Air recirculation maintains humidity and consistent texture.

- High-pressure plenums ensure uniform heat distribution for an even bake.

- Baked biscuits emerge with the desired color, moisture, and crunch or softness.

with auto-rejection system

Option – sandwiching

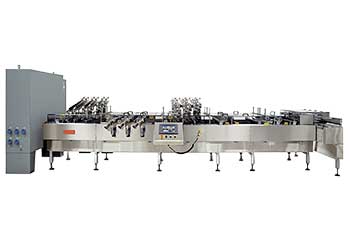

For biscuit manufacturers looking to expand into sandwich products, our Peerless sandwiching technology offers a robust solution.

Available in multiple configurations, the system can produce from several hundred up to 4,800 sandwiches per minute. It accommodates a variety of biscuit shapes and sizes, and supports a wide range of fillings, including cream, peanut butter, cheese, and jelly.

Option – flour reclaim system for biscuits

The Laramore flour reclaim system provides hygienic, efficient recovery of dusting flour on biscuit lines. It reduces labor, recovers up to 96% of flour, removes contaminants, and improves air quality, supporting consistent, safe, and sustainable biscuit production.

See our soft dough high speed mixer in action

Watch the production process from mixing to baking. Discover how Coperion delivers reliable performance, superior hygiene, and consistent product quality at every stage.

Related technologies

Related applications

Get in touch

We take a distinctive approach to the processes that drive manufacturing. Let us know how we can help you achieve your goals for efficiency, productivity and safety.