Powder loader for food & pharmaceutical industries

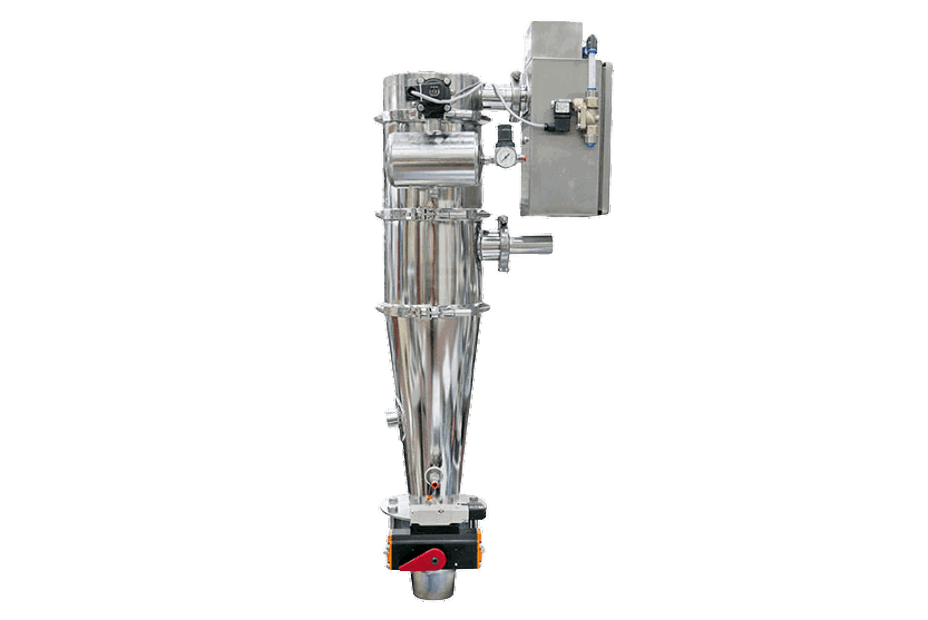

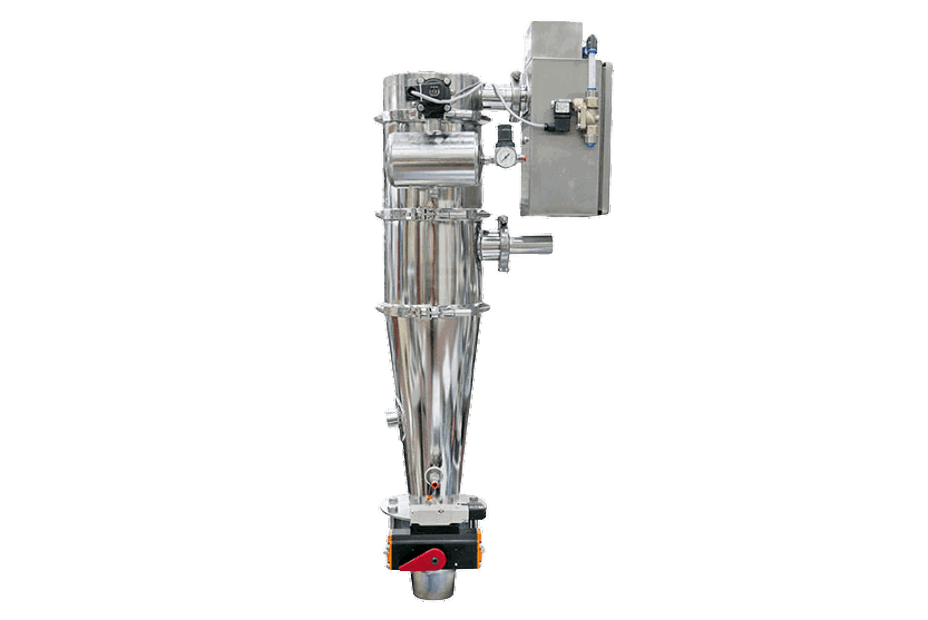

K-Tron P10 loaders are venturi-powered machines designed to convey powders with precision, supporting hopper loading and loss-in-weight feeder refill applications, where the loader is not always emptied completely. These loaders are suitable for food, dairy, nutraceutical, pharmaceutical, and chemical industries, meeting 3A dairy sanitary requirements for hygienic production.

The venturi power unit utilizes compressed air to create a vacuum convey source, ensuring dust-tight and efficient powder transfer.

This receiver is compatible with plastics, chemicals, and mineral processing applications. For more details, please visit the P-series loader page on Coperion performance material website.

- Overview

- Range

- Features

- Gallery

The P-Series P10 loaders provide reliable and sanitary powder conveying for food, dairy, nutraceutical, and pharmaceutical applications. They are suitable for single-receiver operation, feeder refill, or integration with other process equipment. So, they ensure efficient, dust-tight material transfer across production lines.

Hygiene and reliability

The P10 Loader is made from 316L stainless steel with a fully sanitary design. Also, it meets 3-A Dairy and cGMP standards. FDA-approved materials, steep cone angles, and an easy-to-clean design reduce product residue. The enclosed venturi power unit makes maintenance simple. For regulated environments, optional ATEX and NEC versions are available.

Flexible operation

P10 Loaders have powered flap or butterfly valve discharge options for precise powder flow. Then, they can be controlled with LSR controllers and connected to other process systems. So, their strong modular design ensures continuous operation in demanding environments.

| Model | Loader volume (max.) | Conveying rate (max.) | Discharge valve |

| P10-FP-150-VE | 9.5 dm³ (0.34 ft³) | 300 kg/h (660 lb/h) | Power flap Ø150 mm (6 in) |

| P10-BV-100/150-VE | 7.3 dm³ (0.26 ft³) | 300 kg/h (660 lb/h) | Butterfly valve Ø100 / Ø150 mm (4 / 6 in) |

Notes:

- Conveying rates are based on 6 m (20 ft) distance and a bulk density of 0.5 kg/dm³ (31 lb/ft³). Actual rates vary with material characteristics, distance, and plant layout.

- Controls: LSR (Loader Single Receiver) Controller for precise operation.

- Safety options: Hazardous location versions available (ATEX, NEC).

- Hygienic stainless steel construction (DIN 1.4404 / AISI 316L) for durability and easy cleaning

- Discharge options: powered flap or active driven butterfly valve for precise powder flow

- Sanitary and compliant: meets cGMP standards and uses FDA-approved materials

- Enclosed venturi power unit for vacuum generation with minimal maintenance

- Sanitary design ensures easy cleaning and minimal product residue

- Rugged modular construction for reliable operation in demanding environments

- Steep cone angle promotes complete discharge and reduces product build-up

- Large-area reverse-jet filter for efficient, dust-tight powder conveying