Gravimetric liquid feeder for liquids & pastes

Coperion K-Tron liquid feeder is a versatile, high-precision loss-in-weight feeder engineered for accurate, continuous metering of liquids and pastes. Suitable for a wide range of industries, the liquid feeder delivers precise gravimetric or volumetric feeding, ensuring consistent process quality even with temperature-sensitive or viscous materials. Its modular design allows custom configurations to meet the specific demands of each application.

Liquid feeder is ideal for:

- Flavors and aromatics in food and beverage production

- Viscous liquids such as molasses, acids, or plasticizers

- Meat slurry for food or pet food extrusion

- Liquid additives in chemical processes like polyethylene production

Benefits:

- Highly accurate gravimetric or volumetric feeding for liquids and pastes

- Flexible modular design with multiple pumps and tank options

- Reliable performance with temperature-sensitive or viscous materials

- Reduced operational costs compared to traditional feeding systems

- Proven 2 Sigma accuracy for high-value ingredients

- Optional heated units for challenging material properties

- Overview

- Range

- Gallery

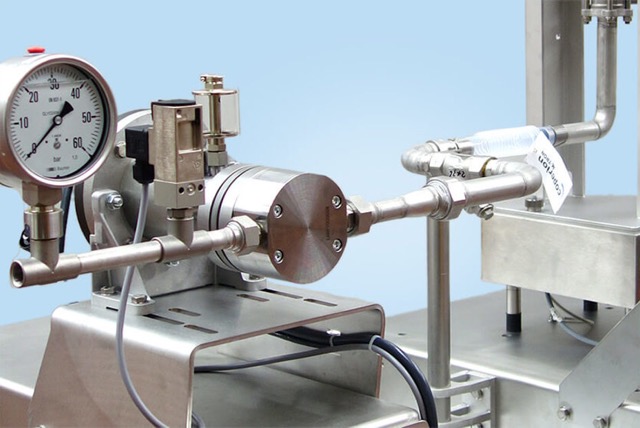

Liquid feeders maintain a continuous, highly accurate flow by weighing liquid or paste on a suspension or platform scale and adjusting the pump rate automatically. This gravimetric control ensures precise feeding while protecting product integrity and reducing waste. Modular by design, the feeders can be tailored with different tanks, pumps, or heated units depending on material characteristics, viscosity, or temperature sensitivity. The system supports downstream integration with mixers or other process equipment as required.

Designed for accuracy and reliability

Built with robust stainless steel and advanced weighing technology, the liquid feeder ensures repeatable accuracy and reliable performance over long-term operation. Special design features, such as the pump located outside the weighing area, simplify maintenance and reduce contamination risk. The feeders achieve outstanding 2 Sigma accuracy, as demonstrated in sample tests with high-value liquids.

Compact, flexible, and easy to integrate

With a modular construction, the liquid feeder adapts to a variety of production layouts, whether installed in single-floor or multi-floor operations. Flexible connection lines allow the tank and pump to be positioned optimally for your process. Available in multiple scale sizes, these feeders can accommodate small- or large-volume requirements efficiently.