Automate your donut production with precision coating and decorating

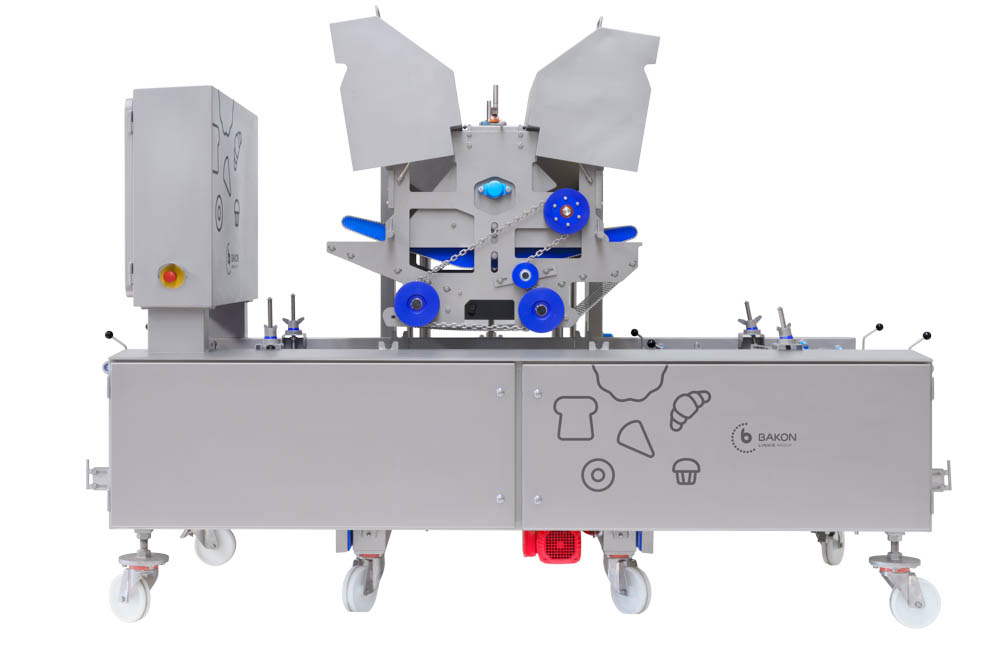

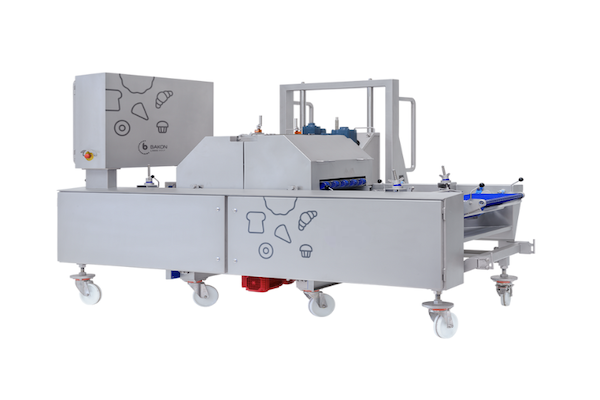

The BAKON dipping machine automates the coating process of donuts and similar products with speed, precision, and consistent results. Designed for industrial bakeries, it streamlines production while supporting a wide range of coatings from chocolate and fondant to glaze, making it ideal for high-output lines and custom decorations.

Available in any desired working width up to 1200 mm, the machine is built on a C-frame as standard. For models with working widths above 800 mm, an H-frame is used to support larger-scale operations. The stainless steel gears inside the gearwheel pump ensure precise control of product flow, and can be rotated backward to relieve pressure and prevent dripping from the nozzles.

Ideal uses include:

- Glazed and chocolate-coated donuts

- Fondant-dipped pastries

- Decorated ring cakes and mini bundts

- Drizzled and topped baked goods

- Mass donut production lines with decoration steps

See the donut dipping machine in action

Automating the donut coating process with consistent, high-speed performance. Watch how donuts are evenly dipped, then decorated with drizzle and toppings for a perfect finish. Ideal for industrial bakeries looking to streamline production and enhance product quality.

Alternatively, watch this on YouTube

- Overview

- Options

- Gallery

The BAKON donut dipping machine is designed for automated, high-capacity dipping and finishing of donuts and similar bakery products. Built to replace slow manual processes, it ensures uniform coating and precise control for consistent results, ideal for industrial bakeries and food production lines.

Precision dipping and versatile decoration options

The machine handles a variety of coatings such as chocolate, fondant, and glaze with adjustable dipping levels to suit different product sizes. Working widths range from 300 mm up to 2000 mm, allowing flexibility for small to large-scale production. Optional decorating modules including the Drizzle Unit and Strewer provide additional finishing touches like striped drizzle patterns and dry toppings such as sprinkles or nuts.

Engineered for hygiene, ease of operation, and line integration

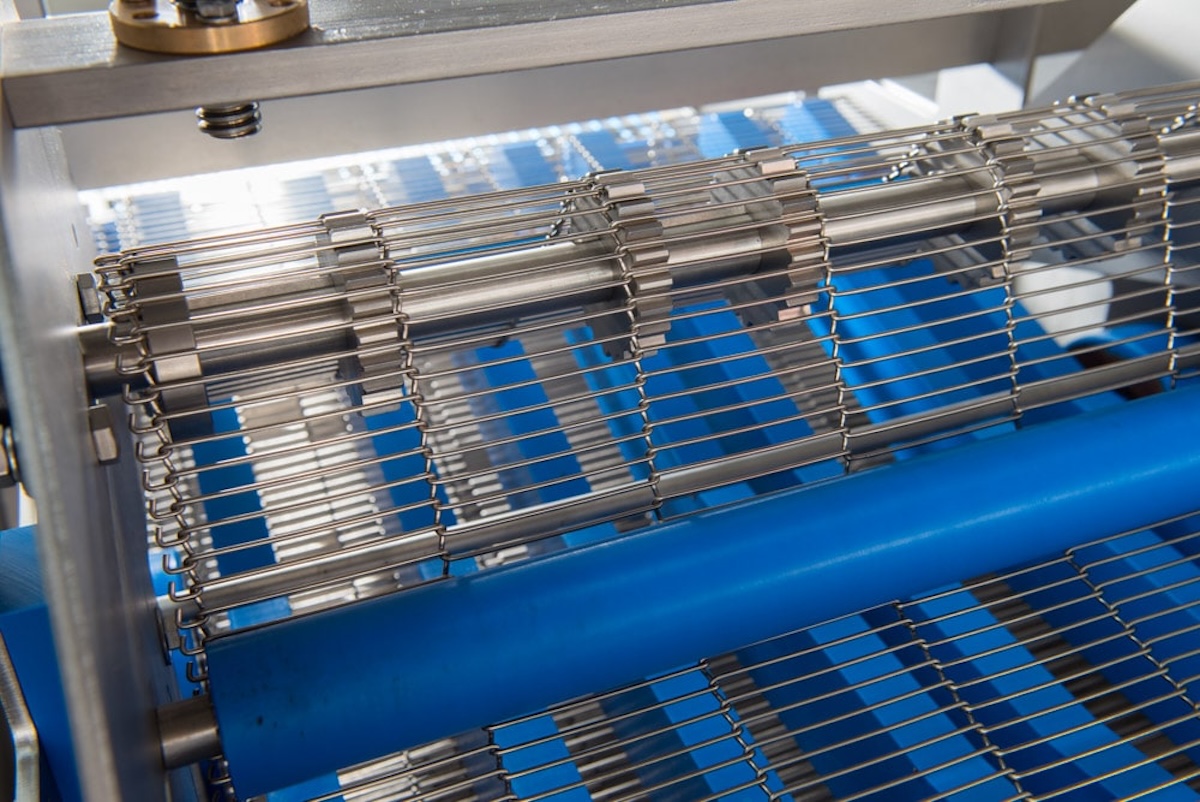

Constructed from stainless steel with hygienic design features, the dipping section is removable for fast and thorough cleaning. The conveyor system uses poly cord belts and wire mesh belts to gently hold products during dipping. A fully adjustable conveyor speed (2–12 m/min) and movable frame with swivel casters support flexible operation. The machine integrates easily as a stand-alone unit or as part of a complete inline donut decoration line.

Robust performance with customizable options and support

Optional covers maintain dipping tank temperature and hygiene, while matching melting tanks keep coatings ready for processing. BAKON offers tailored solutions to fit your specific production needs, backed by expert service and support programs to ensure long-term reliability and uptime.

The GEARWHEEL DEPOSITOR MACHINE is available as stand-alone and inline machine.

- Cover over dipping section: Stainless steel frame with lexan windows to prevent heat loss and contamination; easily removable for cleaning

- Drizzle Unit: Heated container with eccentric screw pump for applying decorative stripes via a zigzag motion on top of the conveyor

- Strewer: Movable C-frame equipped with a funnel for applying dry toppings like sprinkles, nuts, or flakes, activated by a product sensor

- Melting Tank: Double-walled tanks available in various sizes to (pre)heat coatings before dipping or decorating

Download

brochure

To learn more about the donut dipping machine by BAKON, please download our PDF documentation.

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.