Pharmaceutical industry

Processing technologies for the pharmaceutical industry

About Coperion, your trusted partner in the pharmaceutical industry

Welcome to Coperion – discover the future of pharmaceutical processing with us now utilizing the expertise, strength, and quality of industry leading technology brands — DIOSNA, VMI, Kemutec, Gabler, Baker Perkins, and K-Tron.

We offer comprehensive solutions for oral solid dosage forms as well as topical creams/lotions in both batch and continuous processes. Whether from receipt of raw ingredients, excipients and API’s to the final milling, mixing, granulating, drying , extruding, spheronizing and/or coating steps, our integrated systems include contained product transfer throughout. Our medicinal confectionary lines can also provide cooking, mixing, forming and demoulding in both batch and continuous modes.

Why Choose Coperion?

Versatile Options

Batch to continuous processing equipment solutions for solid and liquid products.

Single Source Supply

Full system design for peace of mind – from R&D to production processing.

Specialized engineering teams

ensure GMP-compliant design focused on safety and efficiency and can provide systems suitable for various containment and OEL levels.

Reliable processing

Coperion unites renowned application experts and equipment providers, offering a comprehensive suite of solutions for all your pharmaceutical processing needs.

Applications

The utilization of our portfolio allows the maintenance of uniform procedures from the developmental phase to the production stage. From laboratory to pilot and production scale, from single to complete system designs for solid, semi-solid, viscous, semi-liquid and liquid products – all from one source.

Our processing solutions support the manufacturing of pharmaceutical Rx- and OTC, nutraceutical and consumer health products such as:

Oral solid dosage forms

Processing equipment for solid dosage forms

- Powders, granules, (micro-) pellets

- Coated (micro-) tablets & pellets, dragees, inhalants, effervescent products

- Medicinal gummies

- Excipients

Oral, (epi-)topic products

Processing equipment for oral, topic, and process integrative products

- Pastes, gels

- Ointments, emulsions, oils

- Epidermal patches, implants etc.

- Coating, granulating, and coloring liquids

Operator protection

Equipment standards & options for safe processing

- (Semi-) containment options up to OEB 5

- Explosion protection in accordance with NEC, UL, ATEX

- CIP & WIP

Processing technologies

Coperion’s premium equipment portfolio is planned, tested, engineered, built, delivered, installed, and commissioned from one source according to your specific requirements.

We work closely with clients to deliver tailored, streamlined solutions for every process step, catering for the dynamic needs of pharmaceutical, nutraceutical, and consumer health products manufacturers worldwide. With a corporate operating model which is dedicated to innovation and customer service, our unwavering commitment lies in evolving with global market trends to stay ahead of the curve.

We provide expertise gathered from decades of experience in batch and continuous processing, offering solutions for:

Ingredient

& system automation

We provide ingredient handling options as integrative or full system solutions for batch and continuous applications. Our range of automated and non-automated material handling solutions include pneumatic conveying systems, a variety of loss-in-weight and gain-in-weight feeders, receivers, valves, etc.

Solids:

K-Tron Kemutec (Mucon)

Viscous to liquid:

K-Tron Kemutec (Mucon)

Mixer-granulators

Our granulating solutions range from high-shear granulators to fluid bed granulation processors allowing for wet- and hot-melt or top- and tangential spray granulating. Single unit systems allow for granulating and vacuum drying in one system reducing exposure times. Granulating liquids can be prepared with our liquid mixing equipment.

Solids:

DIOSNA

Liquids:

VMI

Liquid

mixers

Our mixing options enable for most flexibility and a broad application range: mixing semi-solid & liquid, liquid, and viscous products (homogenization, emulsification, dilution, dissolution) from oils to gels and pastes for pharmaceutical and personal care products. Our mixing options with or without vacuum applications cover all stages from R&D to production.

All applications:

VMI

Dispensers

& micronizers

Solids & Liquids: Our range of feeders – can cover many requirements: serving into batch and continuous processes, gaining the highest accuracy though innovative weighing technology, or protecting abrasion-sensitive products by vibrational solutions, and feeding liquids.

We offer milling and sieving options for micro – and homogenizing wet and dry granules.

Solids:

Coperion

Viscous to liquid:

Coperion

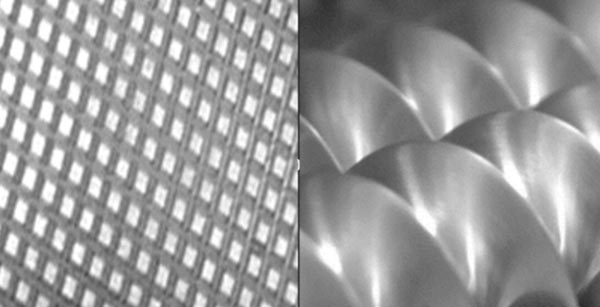

Extruders, spheronizers

& depositors

Solids: We provide integrative or system solutions for wet- and hot-melt extrusion and various requirements. (Non-)Modular solutions allow the highest flexibility and a broad range of processing options.

Viscous to liquid: Our latest innovations in forming or depositing e.g. medicinal or consumer health gummies focused on increasing the efficiency of the manufacturing process.

Solids:

Gabler Coperion DIOSNA

Viscous to liquid:

Baker Perkins

Fluid bed

& vacuum dryers

To obtain optimal solids with defined residual moisture we provide equipment for the fluidized bed processing of granules and pellets where solids are dried by air flow in the process tank. This achieves short drying times of the product at gentle temperatures. Our vacuum drying solutions allow meeting specific product and exposure requirements, while enabling for other particle distribution characteristics.

Solids:

DIOSNA

Drum

& pan coaters

We supply manual and fully automatic coating systems. From drum coaters to onion or pear shape pan coaters, depending on the application.

Innovative spray technology and extensive drying system ensure short and accurate coating.

Solids:

DIOSNA Gabler

Viscous to liquid:

VMI

What we care about

For each of us good health is the highest and most important goal. The success of treatment and the compliance of patients are of the utmost importance to Coperion. After all, every one of us depends on the availability and quality of health products, their efficacy and safety.

Coperion is honored to have already had the opportunity to collaborate with some of the most esteemed companies for the medication of global diseases such as cancer, diabetes, COVID, and much more.

As your partner we strive to enable you to achieve a high-quality, efficient, safe and reliable development and production – at the level that the world’s living beings deserve it.

Download

brochure

To learn more about our Pharmaceutical processing technologies, please download our PDF documentation.

Get in touch

We take a distinctive approach to the processes that drive manufacturing. Let us know how we can help you achieve your goals for efficiency, productivity and safety.

Get in touch

We take a distinctive approach to the processes that drive manufacturing. Let us know how we can help you achieve your goals for efficiency, productivity and safety.

Our technology brands

Baker Perkins is a leading global mixing and forming equipment provider from UK with over 100 years of engineering and process experience in the creation of depositors and cooking systems. This extensive experience in the market has resulted in a continuous stream of innovative gummy manufacturing systems. Designed specifically for the rapidly expanding functional, medicated, and healthcare markets, these machines cater to opportunities in nutraceuticals, sports nutrition, and pharmaceuticals. Employing a starch-free process, these machines ensure maximum hygiene, accuracy, and efficiency throughout the production line.

Find out more: bakerperkins.com

Coperion K-Tron can provide semi-continuous and continuous single source solutions for all of extrusion, feeding and conveying needs in the pharmaceutical, nutraceutical and consumer health industries. K-Tron’s expertise in processing, even the most difficult to handle excipients and active ingredients, has resulted in global recognition of their equipment and engineered services, with a particular strength in providing continuous processing solutions. Many years of experience result in an unmatched level of understanding for material handling and feeding applications.

Find out more: Pharmaceutical – Coperion

The German equipment manufacturer Diosna Dierks & Söhne is one of the world’s leading suppliers of premium batch granulation, mixing, and drying technologies. Already in 1960 DIOSNA invented the pharmaceutical high-shear granulator mixer. The todays machine portfolio include high-shear mixers, fluid bed dryers and drum coaters from lab to production scale – easy to scale-up. The passion DIOSNA’s pharmaceutical technologists, designers, and engineers put in your solution results in reliable, reproducible, safe, and efficient processes, easy machine handling and integration.

Find out more: diosna.com

Gabler Engineering is a globally recognized German equipment provider drawing on decades of experience guarantees state-of-the-art technologies providing components to complete systems: from dosing units, extruders, spheronizer cooling units, lifting columns, feed hoppers, batch portioners and grinders to manual and automated pellet lines. Furthermore, Gabler supplies fully automatic coating onion or pear shape systems using innovative spray technologies and extensive drying systems to ensure the shortest coating times in this sector.

Find out more: gabler.com

Kemutec is a worldwide manufacturer of bulk material handling products specializing in sifting, milling & grinding, mixing & blending and screening equipment. Kemutec offers custom engineered process solutions to the pharmaceutical industry such as dry & wet granulation, tablet reclaim & rework, dry ingredient & blending and ingredient check sifting.

Find our more: KEK Cone Mill – Coperion

VMI is a leading French global expert in mixing technologies, offering solutions for a wide range of pharmaceutical applications. From simple agitation processes to complex operations requiring multiple mechanical effects, VMI designs state-of-the-art mixers and homogenizers to ensure exceptional product quality and stability.

The company’s reliable and modular solutions are tailored to the specific rheology of its clients’ products and accommodate all production capacities, from laboratories and pilot units to turnkey fully automated systems. Engineered for efficiency, they enhance workstation ergonomics, streamline process automation, ensure batch traceability, and deliver scalable results in production, cleaning, and sterilization-in-place.

Find out more: vmimixing.com

Stay updated about Coperion

Then never miss out on the latest industry developments and our news. Our InFocus Newsletter service delivers the latest developments in one neat place or straight to your inbox when you subscribe.

Subscribe here