bakery & Baked goods

Processing quality

bakery and baked goods

with consistency

at any scale

The trusted technology partner of baking artisans and bakery leaders

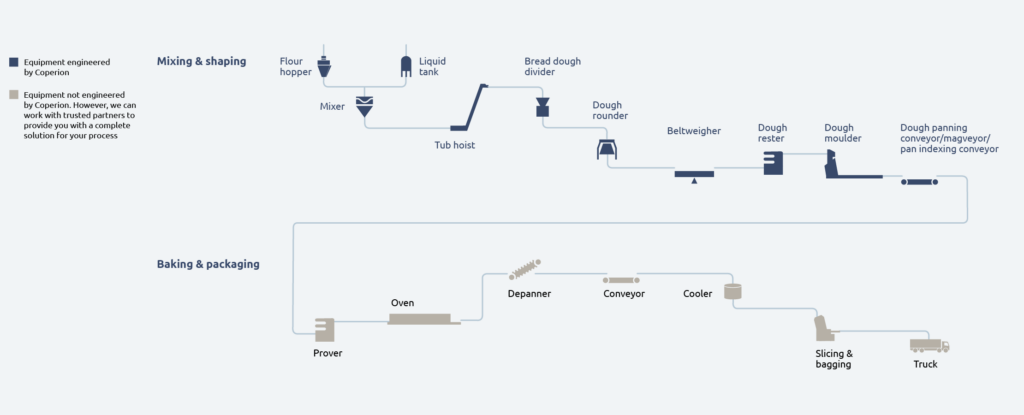

Whether it’s continuous, high-output automated bread baking or small-batch production of premium baked goods, commercial bakeries need dependable, efficient solutions for ingredient automation, fermentation, dough mixing and kneading, dough handling, pre-portioning, dividing, rounding, molding and spraying.

Our baking technologies end-product applications

- Tinned bread loaves for toast and sandwiches

- Premium bread loaves coated with oats, bran or other sprinkled coatings

- Fruited and seeded loaves such as raising bread and rye

- Artisan baked goods such as rustic loaves, brioche, boules or soda bread, including fermented dough breads such as sour dough

- Buns & rolls

- Cakes, including fillings and decorations

- Pizza dough

- Breadcrumbs & panko

- Donuts

A focus on batch consistency

Precision and ingredient automation

No matter what the application or how large (or small) the bakery, the goal is the same: to deliver the best possible product every day. Accurate ingredient control is essential. Our technology enables precise the mixing of both solids and liquids even at the high speeds required for large-scale automated baking. Live temperature sensing and automated feedback enables the process to adapt in real time, delivering the right water temperature and ingredient proportions for consistent results every time.

Total control over fermentation

Pre-dough mixers are a particularly sensitive part of the baking process for bakers working with sourdoughs for example. Thanks to our extensive range of pre-dough fermenters with temperature control by European technology leaders DIOSNA and VMI, your operator will be able to control the action of yeast and LAB acids and keep your daily safety stored ready for action.

Automated dough handling for accurate timing

Automated bowl management solutions, using either rail guides or Automated Guided Vehicles (AGVs) are available to control and automate dough movements in your bakery, limiting the risks of human errors.

The world’s most extensive range of commercial and industrial bakery mixers

From lab-scale to full production lines, Coperion and its technology brands simply offer the world’s most extensive range of batter, cream and dough mixers available on the market.

Batter and cream mixers (learn more)

- Vertical batter and cream mixers

- Horizontal batter and cream mixers

- Continuous batter and cream mixers

Dough mixers and kneaders (learn more)

- Vertical dough mixers for commercial and industry applications.

- Artisanal and industrial spiral mixers by VMI, building on the excellence of artisanal French bread making tradition.

- Wendel mixers, by DIOSNA, which greatly reduce kneading time even further thanks to proprietary agitators.

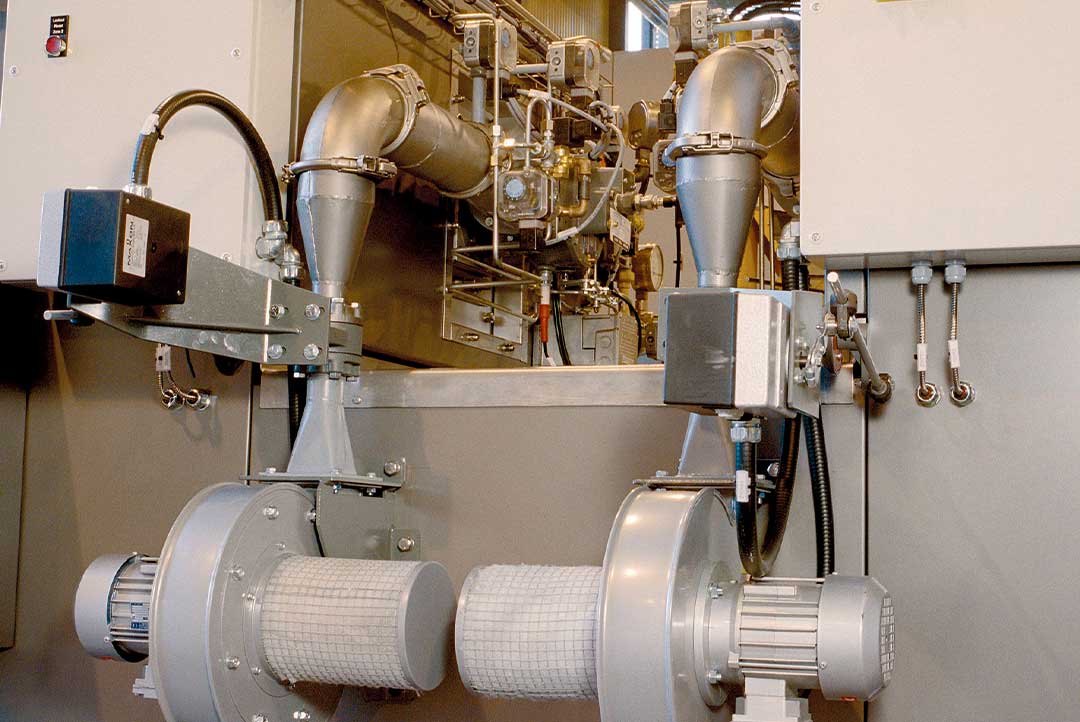

- High-speed mixers by Baker Perkins – which are renowned for kneading the dough in vacuum-controlled environment: the Chorleywood Bread Process (CBP).

- Horizontal mixers, for bakeries aiming for larger production capacity.

- Triple Roller bar horizontal mixer, prefered for bread dough kneading, is available by Shaffer, also in Sigma Arm configuration.

- Pioneer mixer, a versatile medium duty mixer, is also available by Peerless for bakeries interested in changing the agitator types.

- Continuous mixers, including VMI’s Verymix, the world’s leading continuous mixer for the production of par-baked and frozen dough.

Expert of frozen and par-baked applications

For companies working in cold supply chains and aiming to bring frozen dough or par-baked baked goods to proximity baking stations, our portfolio integrates solutions to support you a range of active cooling systems for both vertical, horizontal mixer bowls, including continuous mixers, that help to lower the dough temperature during the kneading process, limiting yeast activation and saving precious energy for your downstream cooling process.

Technologies for cakes and pastries

By reducing downtime and improving productivity, we help keep your bakery operating at its peak potential.

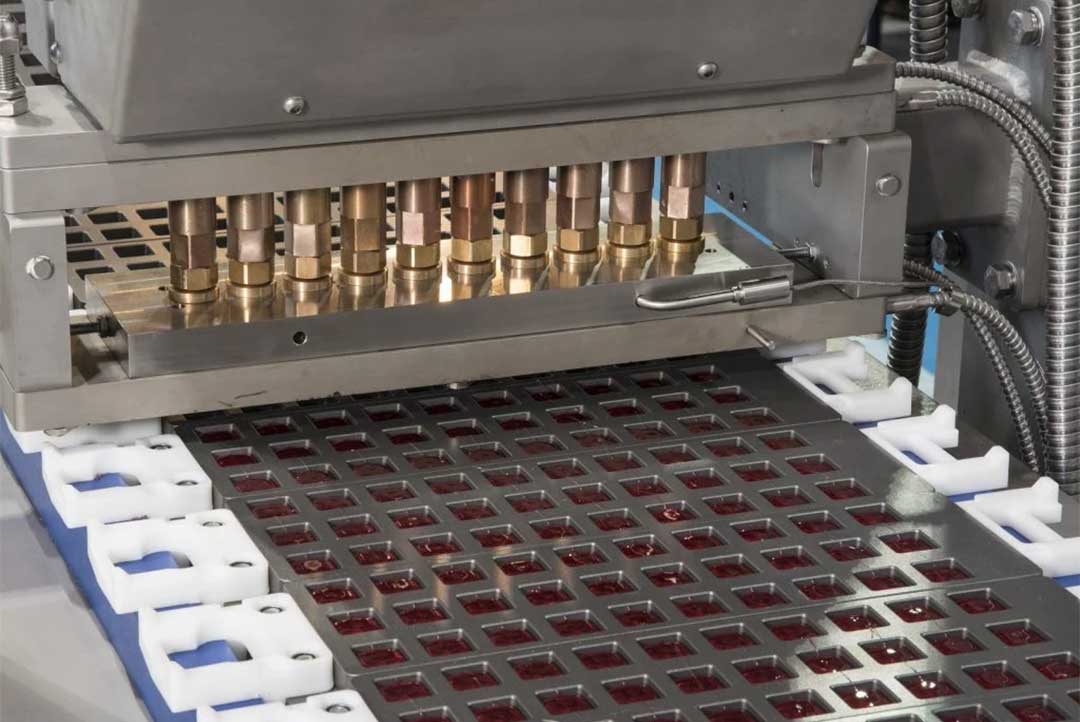

Bakery depositors (learn more)

Designed to precisely control doses and automate operations like filling and layering. Unifiller and Bakon offer a full range of cake automation solutions for your pastry and and cake operations. From individual stations to full cake automated lines.

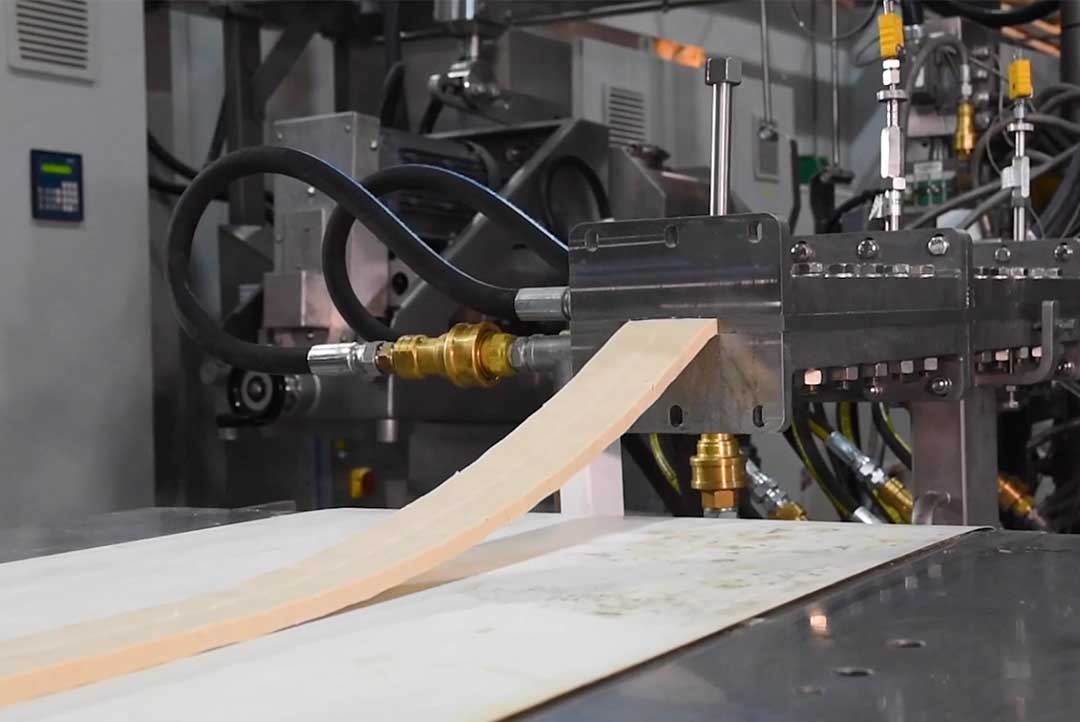

Spraying of ingredient and release-agents (learn more)

Prepare for baking and automate the spraying of release-agents or ingredients like egg-wash with our first-class spraying machines by Bakon.

Elevate your products with delicious enrobing and decoration

Give the final touch! Our automated enrobers, dippers and drizzlers, available from Bakon and Unifiller, provide the finish required to elevate your final product.

Generating efficiencies for the bakery industry

Kemutec provides quality and safety in baking applications through sifting solutions.

An unmatched global network of technology brands

Aside from our main Coperion brand, we also gather the application expertise and manufacturing capabilities of 9 globally recognized bakery industry leaders. This global network of experts, test centers and manufacturing capabilities is unparalleled in the bakery industry and ensures we can support your bakery with total solutions.

The Coperion difference

Tailored solutions

Test kitchens to match your recipe to local tastes, custom manufacturing and expert integration of our technology into your facility.

Compliance certification guaranteed

Technology ATEX type certified for Zone 20 internally and 21 externally, and EU Food Compliant (EC) No 1935/2004.

Gentler handling

Our mixers, rounders and formers are designed to reduce dough damage to reduce waste and maintain the highest quality.

Related solutions

Get in touch

We take a distinctive approach to the processes that drive manufacturing. Let us know how we can help you achieve your goals for efficiency, productivity and safety.