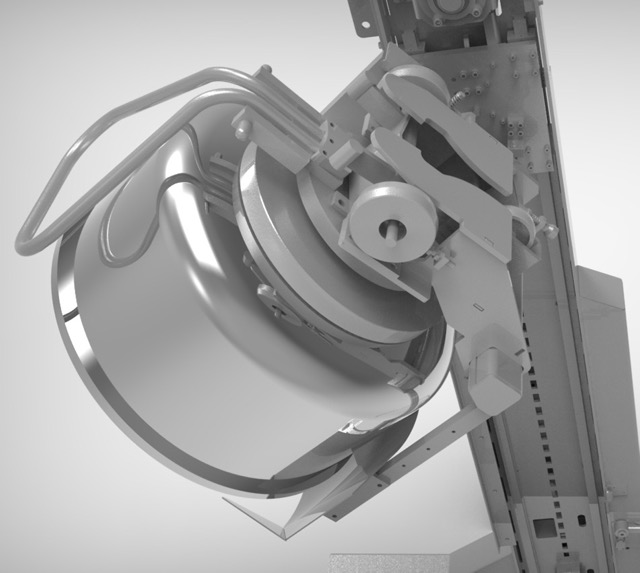

Inclined & vertical bowl elevator and tipper

DIOSNA elevator tippers lift and dump dough tubs efficiently, from small craft bakeries to large industrial operations. Available in mobile or stationary versions, they feature robust construction, versatile column designs, and safety-focused mechanisms. Optional features like frequency converters and adjustable tipping heights ensure seamless integration into any workflow.

Key benefits:

- Streamlined dough handling for faster production.

- Compact designs that save floor space and allow additional installations.

- Safe, reliable operation with durable mechanical and electrical safeguards.

- Versatile configurations to suit different workflows, tub sizes, and production volumes.

- Overview

- Range

- Gallery

DIOSNA elevator tippers HK range is designed to streamline dough handling and optimize production in bakeries of all sizes. Mobile or stationary options provide versatile solutions, while robust construction and safety-focused mechanisms ensure reliable, long-term operation. Optional features like frequency converters, adjustable tipping heights, and overhead drives enhance workflow integration and efficiency.

Reliable performance across batch sizes

Models handle dough tubs from 600 kg (HK 170) up to 2,000 kg (HK 1000), with tipping heights from 2.10 m (HK 170 in stationary use) up to 5 m (HK 1200). Flexible column designs and multi-gear motors allow smooth lifting and continuous production, whether for small craft bakeries or large industrial operations.

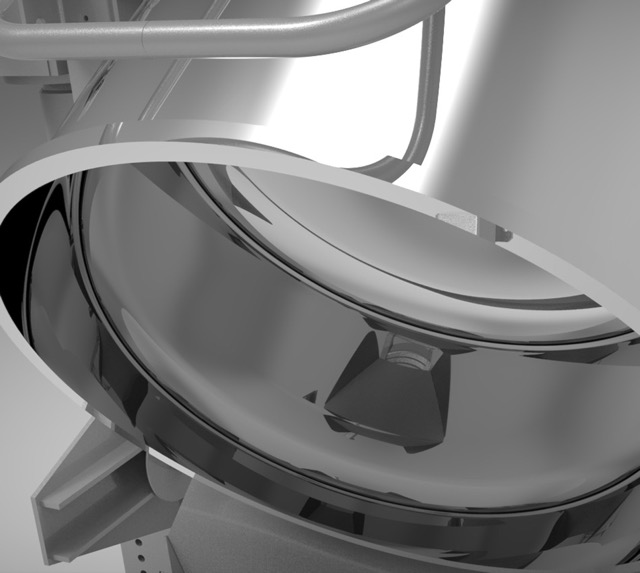

Hygienic and robust construction

All systems feature stainless steel frames, compact footprints, and durable mechanisms designed for 3-shift industrial use. Safety catches, toothed-rack locks, and electrically secured safety bars ensure secure operation during lifting and tipping.

Operator-friendly controls and flexible integration

Elevator tippers can be used standalone or integrated into fully automatic systems. Optional configurations, such as mobile or stationary setups, inclined or vertical columns, and compatibility with different vats, allow bakeries to adapt the equipment to their specific workflow and production needs.

Elevator tipper HK 170

- Floor or table use, supports various bowl sizes

- Easy handling, low maintenance

- Max load: 600 kg , tipping height: 2.10 m

- Safety: toothed-rack lock, catch, secured bar

- Weight: 800 kg, up to 6 tippings/hour

Elevator tipper HKV 224

- Column usable vertically or inclined

- Mobile or stationary, manual or automatic operation

- Supports various bowl sizes, optional bowl scraper

- Overhead drive saves space, ensures safety

- Load up to 1,500 kg, tipping height 3.5 m

- Standalone or fully automatic integration

Elevator tipper HK 300 – HK 600

- Column vertical or inclined

- Mobile/stationary, manual or automatic

- Various bowl sizes, optional scraper

- Overhead drive saves space, ensures safety

- Load 1,500 kg, tipping height 3.5 m

Elevator tipper HK1200

- Space-saving vertical design

- Robust for 3-shift operation

- Secure bowl hold with tong lock

- Load up to 1,200 kg, tipping height 5 m

- Up to 16 tippings per hour

Elevator tipper HK 170

Elevator tipper HKV 224

Elevator tipper HK 300 – HK 600

Elevator tipper HK1200

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.