Ultrasonic cutting technology for maximum precision

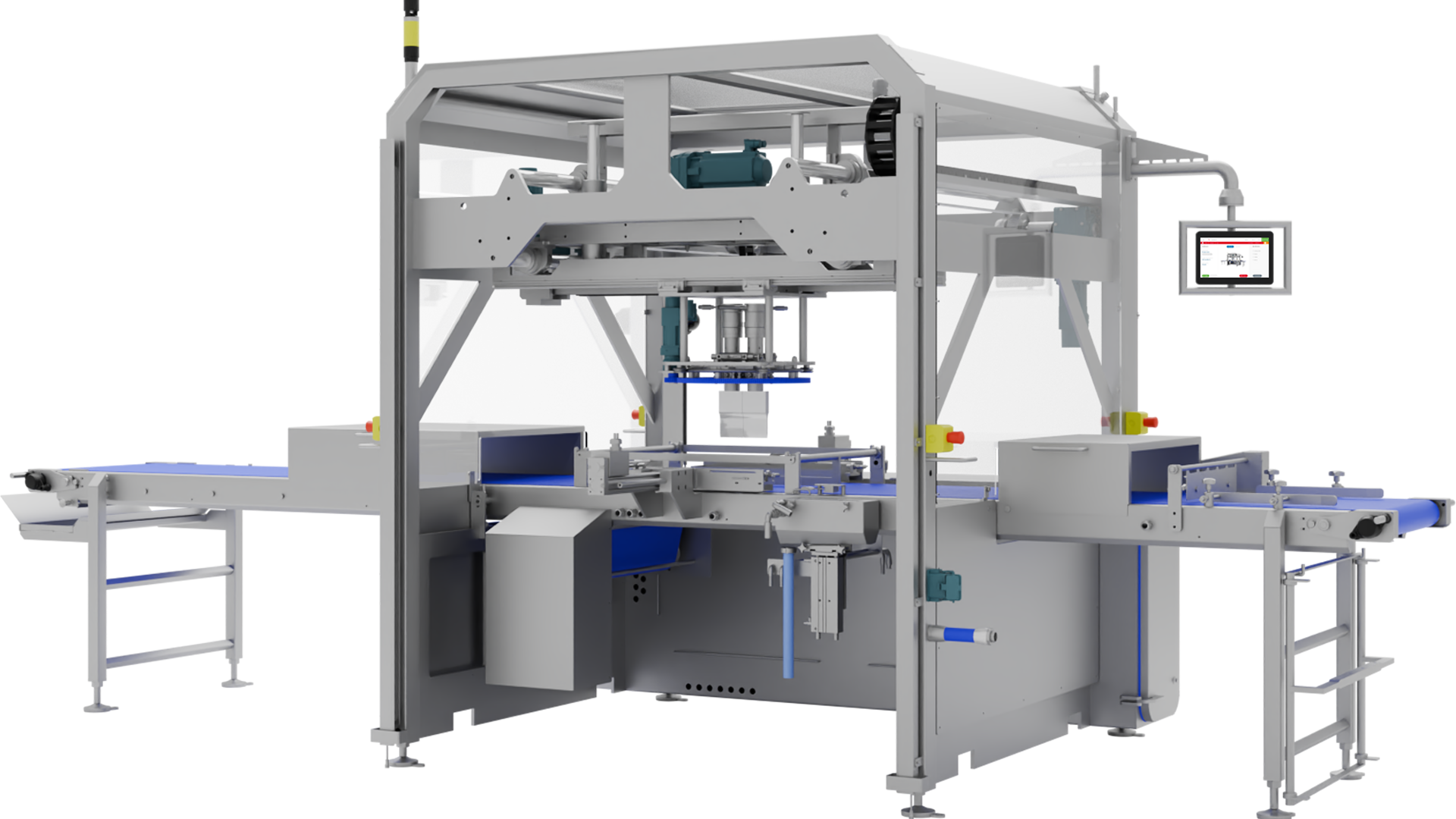

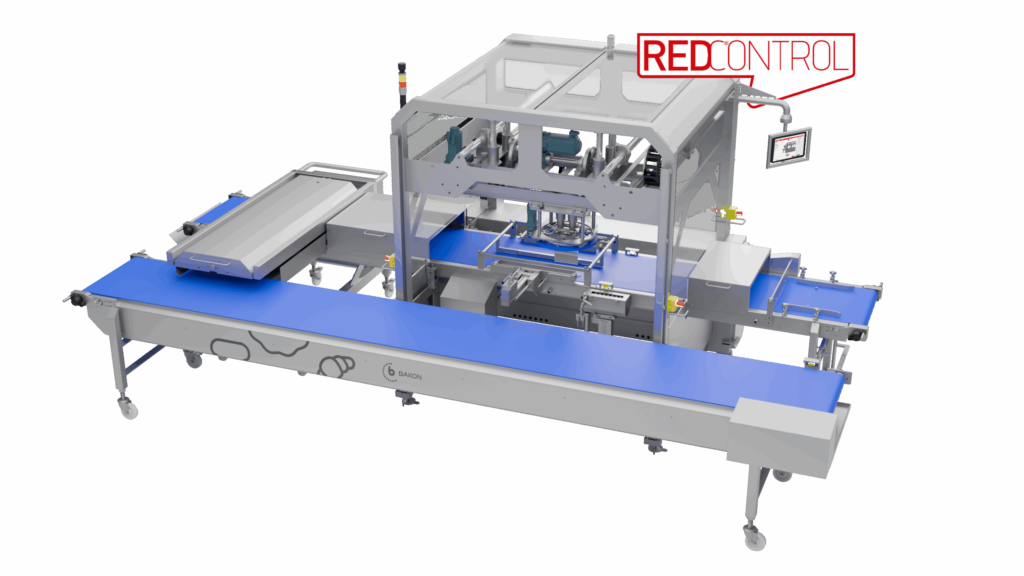

The BAKON Inline ultrasonic slicer delivers high-capacity, precise, and labor-saving cutting of bakery and confectionery products. Ideal for industrial bakeries, caterers, and large-scale production lines, it handles items from single portions to full trays of cakes, pastries, and other baked goods. High-quality titanium ultrasonic blades ensure clean, accurate cuts while preserving product quality and appearance.

Its full-color touchscreen lets operators set, save, and recall cutting patterns, while the servo-driven bridge ensures precise slicing of both round and rectangular products. Optional features such as the automatic blade cleaning unit and remote access modem reduce downtime, and the inline setup allows seamless integration into production lines.

Ideal uses include:

- Cakes, pies, pastries, pizzas, quiches, muesli bars, and other confectionery products

- Fresh and deep-frozen products

- Product trays up to 800 x 600 mm; round products up to Ø 380 mm

- Stand-alone or inline production setups

- Medium to high-capacity bakeries seeking efficient, precise slicing

Application examples

See the Inline ultrasonic slicer in action

Watch the BAKON Inline ultrasonic Slicer at work – efficiently slicing cakes, pastries, and more with precision ultrasonic blades and simple touchscreen controls.

Alternatively, watch this on Youtube

- Overview

- Options

- Gallery

- Resources

The BAKON Inline ultrasonic slicer is a high-capacity, precision slicing solution for bakery and confectionery production. It delivers fast, accurate portioning for cakes, pies, pastries, quiches, muesli bars, and other baked or frozen products. Using ultrasonic technology, the Inline Slicer ensures clean, consistent cuts with minimal product waste while preserving appearance and quality.

Consistent cutting quality with scalable output

Equipped with halfwave or fullwave titanium blades (standard 315 mm) mounted on a servo-driven bridge, the Inline Slicer handles both round and rectangular products on trays up to 800 x 600 mm, with round products up to Ø 380 mm. Cutting patterns such as squares, triangles, or diamonds, can be programmed, saved, and recalled via the full-color touchscreen, enabling repeatable precision in high-volume production. Suitable for medium to high-capacity bakeries, the Inline Slicer operates as a stand-alone unit or integrated inline with production lines.

Designed for hygiene and ease of operation

Constructed from stainless steel and corrosion-resistant materials, the Inline Slicer is easy to clean and maintain. Its revolutionary UV-C cleaning system cleans and disinfects blades in as little as 20 seconds. Optional features include automatic blade cleaning, a Servomatic rotation device for round products, and quick-fit blade systems for flexible tray sizes. For inline setups, the machine ensures HACCP-compliant hygiene while maintaining high production throughput.

Reliable operation and process control

The intuitive full-color touchscreen provides complete control over cutting patterns, product specifications, and production speed. Optional personal key cards secure access, and the built-in modem enables remote service and support. With its high-capacity design, labor-saving automation, and hygienic operation, the Inline ultrasonic Slicer is a dependable solution for modern industrial bakery and confectionery production.

- Cleaning unit – First the blades are cleaned on both sides with water in a fully waterproof sealed station; next a scraper removes any residues and then dries the blade. Thorough disinfection takes place in two other stations with UV-C light. The complete cycle requires 20 seconds and can be done after each product, after 5 or 10 products or at the end.

- Servomatic rotation device – For round products

- Wide choice of cutting blades

Download

brochure

To learn more about the Inline Ultrasonic slicer by BAKON, please download our PDF documentation.

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.