High-performance continuous mixer for industrial bakery and food processing

The Peerless continuous mixer is engineered to efficiently mix and aerate a wide range of food products including cake batter, crème fillings, icings, marshmallow, whipped cream, and butter. Designed for industrial bakery and food processing lines, it ensures unmatched consistency, uniform cell structure, and precise specific gravity for every batch.

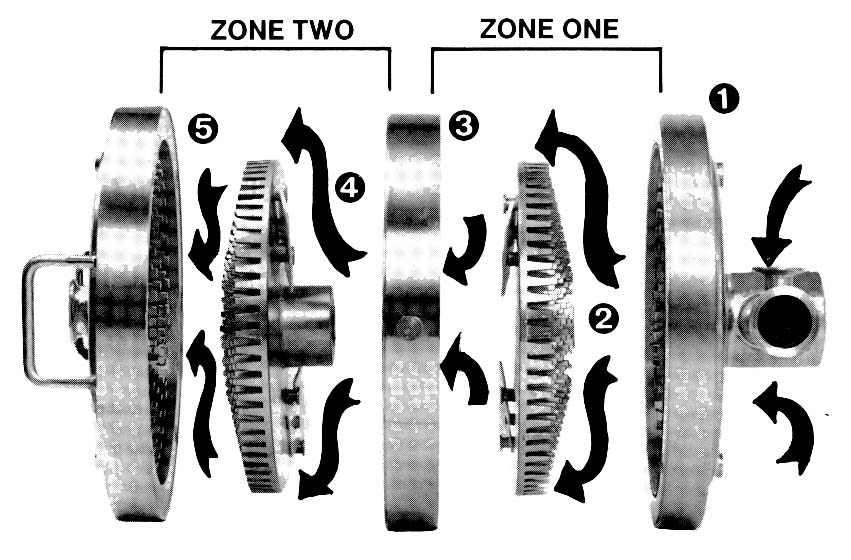

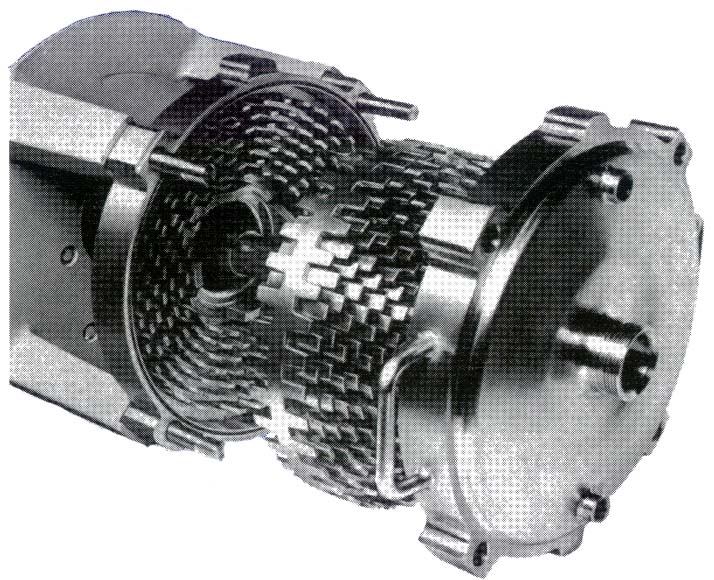

Equipped with a stainless steel mixing chamber with high-strength pyramid-shaped teeth, the mixer provides faster, more efficient mixing at lower speeds, reducing energy costs and heat transfer to the product.

Ideal uses include:

- Cake batters, icings, and crème fillings

- Whipped cream, butter, and marshmallow

- Continuous aeration and high-shear mixing applications

- Overview

- Range

- Options

- Gallery

The continuous mixer features rotor and stator combinations, including front and rear stators made of double-walled stainless steel for coolant circulation and precise temperature control. The sanitary positive displacement pump ensures smooth, hygienic operation, while the open-frame design allows easy access for maintenance.

Its continuous aeration head can process 100+ pounds per hour of cream, ensuring uniform product texture and quality across production runs.

Consistent mixing quality with scalable output

The Peerless Continuous Mixer adapts to varying production needs, handling cake batter, icings, crème fillings, marshmallow, whipped cream, butter, and other food products. Its rotor-stator design and high-strength pyramid-shaped mixing teeth allow faster, more efficient mixing at lower speeds, reducing energy consumption while maintaining product integrity. The unit is suitable for both stand-alone and inline bakery production setups with medium to high output.

Designed for hygiene and ease of operation

Built entirely in stainless steel and corrosion-resistant materials, the Continuous Mixer is easy to clean and maintain. Optional features, including a refrigeration unit, hinged front stator, mass flow meter, color injection system, rotor cooling, and inline temperature probe, allow precise process control and optimize production efficiency.

Reliable operation and process control

From its simple, intuitive control panel to its adjustable mixing and aeration settings, the Continuous Mixer is designed for accurate, repeatable performance. The unit’s stainless steel pump and connections ensure sanitary operation, while optional features like rotor cooling or inline temperature monitoring further enhance flexibility and product quality.

| Model | Capacity |

|---|---|

| CM-6-F | 0–34 kg (0–75 lbs) |

| CML-15-F | 45–363 kg (100–800 lbs) |

| CMH-15-F | 91–545 kg (200–1,200 lbs) |

| CML-25-F | 159–1,089 kg (350–2,400 lbs) |

| CMH-25-F | 204–1,633 kg (450–3,600 lbs) |

| CML-35-F | 272–2,182 kg (600–4,800 lbs) |

| CMH-35-F | 590–3,266 kg (1,300–7,200 lbs) |

Optional features

- Refrigeration unit

- Hinged front stator for easy cleaning and alignment

- Mass flow meter for precision control of specific gravity

- Color injection system

- Rotor Cooling

- Inline temperature probe

- Stainless steel cabinet enclosure

Download

brochure

To learn more about the Continuous mixer by Peerless, please download our PDF documentation.

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.