PET FOOD APPLICATIONS

Pet hard biscuit treats

Coperion’s pet hard biscuit manufacturing technologies provide seamless, scalable solutions for producing pet biscuit at scale in compliance with human food-safety levels. Our production lines are engineered for high production output and long-term performance for global manufacturers.

Scalable solutions for pet treat manufacturing

Pet hard biscuit treats are a popular option for pet treats, including dogs and cats. They can come in various sizes, shapes and flavors to fit the preference of both our furry friends and their human parents.

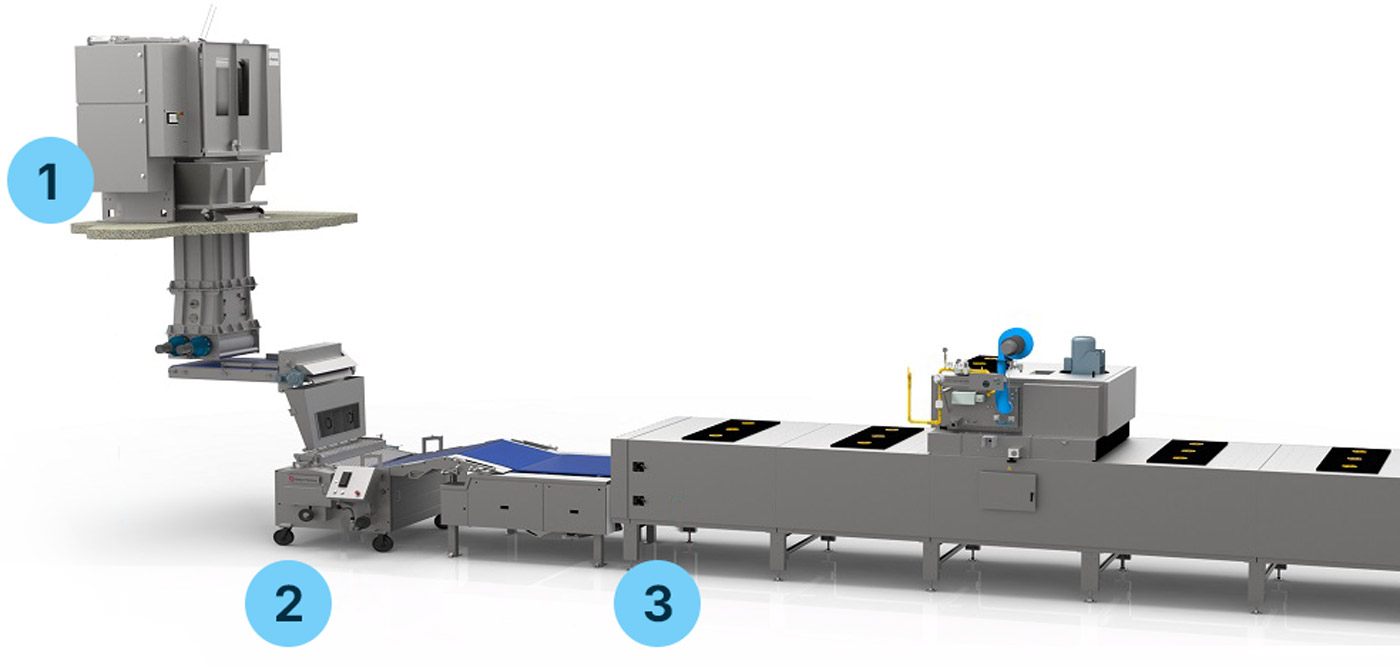

A popular option for the production of pet biscuits is to use a rotary sheet cutting production system, which allow cut out precise shapes at the desired thickness.

Coperion can support pet treat producer with hygienic medium to high volume automated lines which are designed to reduce waste and optimize energy consumption.

How pet treat manufacturing works

Mixing & dough Feed

The process begins with a vertical high speed mixer, designed for efficient, uniform mixing of pet biscuit doughs with various nutritional inclusions. Its shaftless blades accelerate dough development while preserving inclusions. Batch sizes range from 85 to 385 kg, supporting outputs of 2,380 to 5,390 kg/hr.

Alternatively, for specialty or inclusion-heavy doughs, horizontal sigma arm mixers are also available. These mixers provide gentle yet thorough mixing with precise ingredient distribution. Batch sizes range from 600–2,450 kg , depending on the model.

Once mixed, dough is transferred through dough feed systems tailored to production needs. These hygienic systems handle both bulk and metered feeds, with options for dough resting and conditioning to ensure consistent quality.

For mid-scale production, the pioneer medium duty mixer is a versatile solution fitted with a sigma arm agitator. It combines robust dough handling with efficient mixing, making it well-suited for doughs with inclusions or higher viscosities while ensuring consistent batch quality.

Once mixed, dough is transferred through dough feed systems tailored to production needs. These hygienic systems handle both bulk and metered feeds, with options for dough resting and conditioning to ensure consistent quality.

Sheet forming

Pet biscuit dough sheets are formed using the TruClean™ three roll sheeter, which compresses and conditions dough while recycling trim efficiently.

For laminated biscuits, the vertical cut sheet laminator creates controlled multi layer sheets with excellent weight distribution and alignment.

The TruClean™ gauge rolls then precisely reduce the dough sheet to the desired thickness, ensuring uniformity and minimizing waste.

Cutting & dough recovery

Dough sheets for hard biscuits are precisely gauged and cut using the TruClean™ rotary cutter, delivering consistent shapes with high efficiency. The system features quick die roll changes and an easy-to-use HMI for smooth operation. Any excess dough is efficiently recovered and recycled back into the process, minimizing waste and ensuring consistent dough usage before baking.

Baking & handling

Pet biscuits are baked using the TruBake™ range of ovens,each tailored for specific biscuit types and baking requirements.

Convection oven ensures even baking for delicate or thinner products.

When required, the biscuit handling systems efficiently transport biscuits from oven outfeed to wrapping machines. These modular systems have cooling conveyors that can be single or double tier based on the factory layout. They also include servo-controlled channelling boards that guide biscuits into neat lanes. Stacking units prepare biscuits in an upright position for packaging or further processing.

Option – flour reclaim system for biscuits

The Laramore flour reclaim system provides hygienic, efficient recovery of dusting flour on biscuit lines. It reduces labor, recovers up to 96% of flour, removes contaminants, and improves air quality, supporting consistent, safe, and sustainable biscuit production.

Related technologies

Related applications

Get in touch

We take a distinctive approach to the processes that drive manufacturing. Let us know how we can help you achieve your goals for efficiency, productivity and safety.