PET FOOD APPLICATIONS

Dry kibble pet food

manufacturing technology

Coperion’s end-to-end dry kibble cat and dog food production solutions. Explore high-efficiency, food-grade technologies that ensure consistent quality, safety, and performance across every step of the process.

Hygienic kibble production at scale

Producing dry kibble at scale requires more than just capacity—it demands precision, efficiency, and reliability. Coperion delivers fully integrated solutions that support high-throughput pet food manufacturing while maintaining consistent product quality and minimizing downtime. From intake to packaging, every step is engineered for optimal performance.

Importance of food safety

Today’s pets are more than companions—they’re family members who share our homes, often living, playing, and even eating in the same spaces as children. That’s why food safety in pet food production is paramount. Coperion’s technologies are designed with hygienic, food-grade features that meet human-grade safety standards. Open-frame structures, smooth stainless steel surfaces, and easy-to-clean designs help prevent contamination and ensure every kibble is produced with the same care as food for our own tables.

Limiting breakage at every step

Minimizing kibble breakage is critical to maintaining product integrity and brand quality. Coperion’s systems prioritize gentle handling at every stage—from precision feeding and low-velocity conveying to controlled discharge and hygienic packaging—ensuring that each kibble reaches the bag intact and uniform.

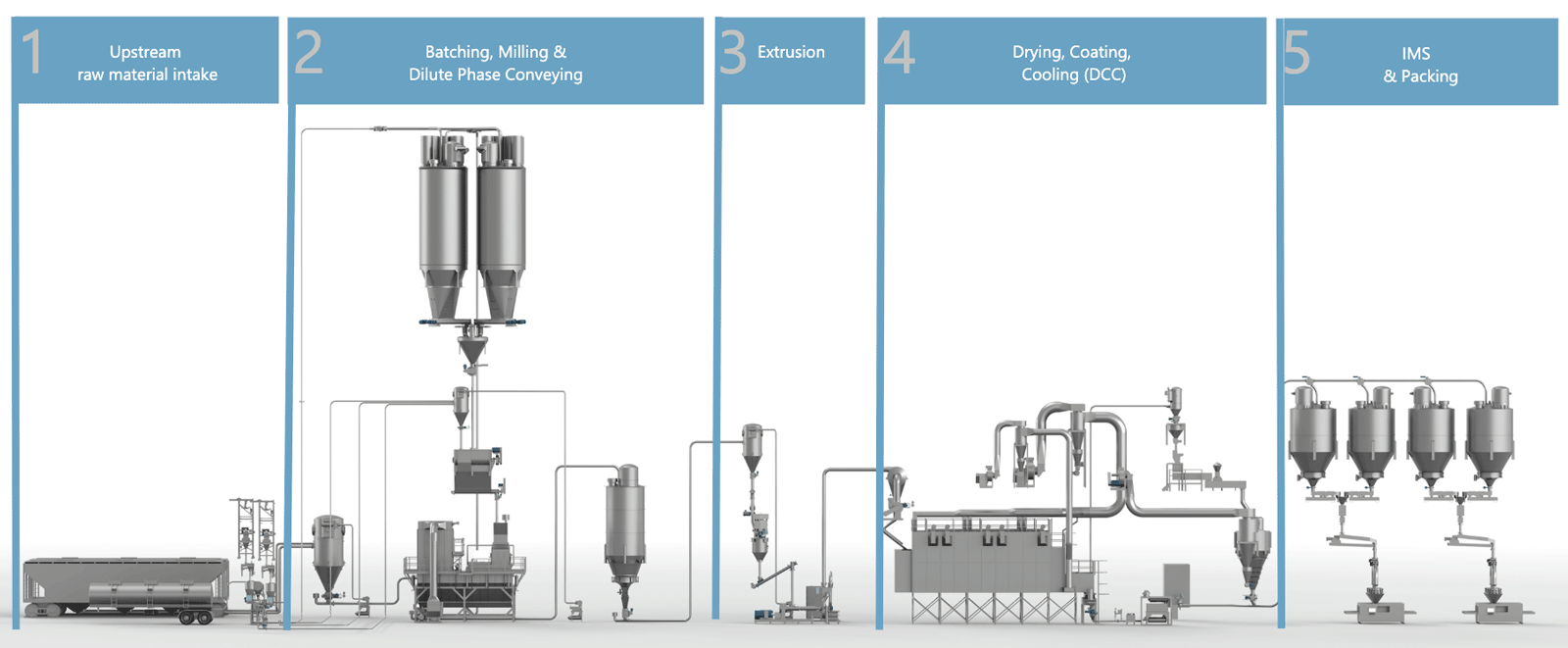

How dry kibble production works

Upstream raw material intake

The journey of dry kibble production begins with a robust and hygienic upstream raw material intake process, designed for efficiency, flexibility, and compliance.

Coperion’s solutions start with above-ground bulk unloading systems for truck deliveries, enabling streamlined intake of large volumes. Conveyors with their dust proof design, ensure a safe, compliant transport of materials within the facility.

For smaller input sources, our modular bulk bag discharge systems support FIBCs in a dust-free environment and are compatible with both volumetric and gravimetric feeding.

Additional manual handling is supported via ergonomic sack tip stations.

All solid material flows—whether major ingredients, minor components, or palatants—are precisely metered using our full range of volumetric and gravimetric feeders, ensuring accurate batching from the very first step.

For your liquid ingredient handling requirements such as vegetable oils and choline chloride, Shick Esteve tank and tot systems will be able to store, pump, dispatch and blend.

Batching, milling & dilute phase conveying

As the kibble production journey continues, precise batching and gentle handling become critical to maintain ingredient quality and consistency.

Coperion’s MCF PowerSaver Grain Storage Air Filtration system ensures efficient dust collection with cleaning capacities exceeding 250,000 CFM and medium-pressure operation (7–9 psig), delivering up to 50% savings in operational costs.

For uniformity in formulation, Kemutec Ribbon Mixers produce homogeneous powder blends, forming a consistent base for further processing.

Grain grinding is optimized through the versatile Kemutec Cone Mill, capable of reducing 10 mm particles down to below 250 microns, with interchangeable cones to suit various textures. For ingredients that demand ultra-fine grinding—down to below 20 microns—the Kemutec Universal Mill offers high-precision milling from 3 mm input sizes.

To transport light or fragile materials, our EDIP (Enhanced Dilute Phase Conveying system) operates below 0.7 barg and uses a proprietary real-time algorithm to manage air velocity, ensuring gentle, efficient transfer while minimizing ingredient breakage.

while preventing contamination

Extrusion

The extrusion phase is a pivotal point in the dry kibble production journey, where precise control and hygienic handling define the quality of the final product.

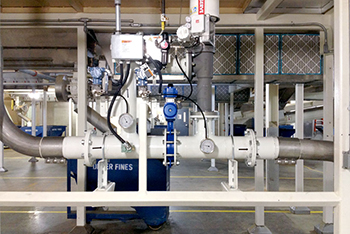

It begins with high-accuracy feeding, made possible by our compact coriolis flow meter, which delivers a continuous, metered flow of raw materials with ±0.5% accuracy.

To manage material direction and flow control pre and post extrusion, Coperion offers a full portfolio of discharge and conveying valves as well as diverter valves, essential for ensuring seamless transitions, minimizing cross-contamination, and optimizing process flexibility.

For extrusion, a comprehensive range of extruders is available through Coperion and our partners, tailored to match specific product and performance requirements—our experts are available for consultation to help determine the ideal solution.

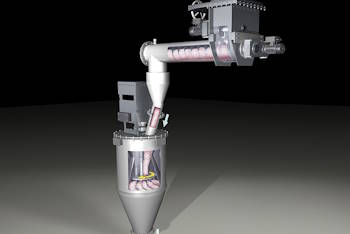

Following extrusion, hygiene remains paramount: enclosed transfer systems such as the Supplied Air Extruder (SAE) Negative Airlift system system prevent post-extrusion contamination by securely conveying kibble to the dryer in a sealed environment with clean air filtered through a HEPA filter.

To finalize this transition, the Horizontal Material Separator (HMS) efficiently separates product from the airstream while accommodating various kibble sizes—all in a space-saving design with up to 50% less footprint compared to traditional cyclone systems.

with its unique “slug” flow

Drying, coating & cooling (DCC)

As the dry kibble production journey enters the critical Drying, Coating, and Cooling (DCC) phase, product integrity and hygiene remain top priorities.

To transport freshly extruded kibble to downstream processes with minimal breakage, Coperion’s E-Finity Dense Phase Conveying system offers a uniquely gentle solution. Utilizing a low-velocity “slug” flow method, it significantly reduces product degradation while operating on low horsepower, making it both energy-efficient and compact—ideal for modern pet food facilities.

To ensure an added layer of product quality and safety, the KEK Centrifugal Sifter provides continuous inline sifting, efficiently removing oversized or foreign materials before the coating phase. Together, these technologies support a seamless transition through drying, liquid and powder coating, and final cooling—ensuring kibble meets the highest standards in texture, safety, and consistency.

IMS & packing

The final stage of the dry kibble production journey—IMS and Packaging—demands precision, hygiene, and efficiency to ensure product integrity right through to bagging.

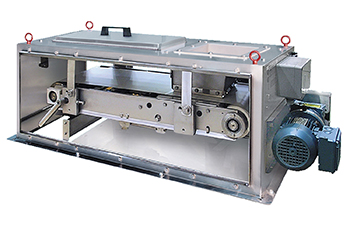

Coperion’s DEA Open Frame Weighbelts provide accurate, continuous weighing and feeding of delicate kibble with exceptional precision, all within a food-grade, open-frame design that supports frequent and thorough cleaning cycles—ideal for maintaining hygiene in high-throughput environments.

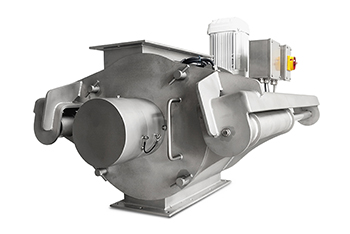

As an alternative to weighbelts, our cleanable rotary pocket feeders offer a reliable solution for continuous product feed into packaging lines. Built with food-grade stainless steel and engineered for easy access, these feeders ensure both operational efficiency and sanitary compliance. Together, these solutions complete the production process with the same care and precision that began at intake—delivering high-quality kibble, ready for market.

See our dry kibble line in action

Producing the highest quality product is at the top of your mind. Your system must minimize product degradation, eliminate inefficiencies and ensure product safety. Because your process is unique, customized system upgrades are preferable to a one-size-fits-all solution.

Related technologies

Related applications

Get in touch

We take a distinctive approach to the processes that drive manufacturing. Let us know how we can help you achieve your goals for efficiency, productivity and safety.