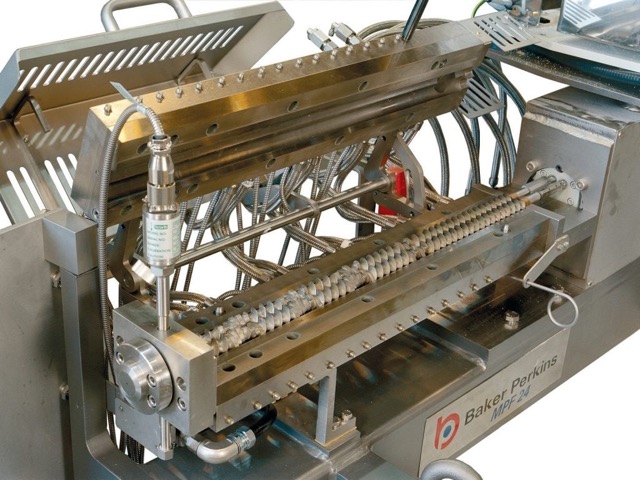

Food extruder for precise small-batch processing

The MPF24 small batch twin screw extruder from Baker Perkins is ideal for laboratory trials, product development, and small-scale production. Its flexible design allows easy testing of ingredients, flavours, and colours while providing reliable data for scaling up to full production.

The MPF24 small batch twin screw extruder is ideal for:

- Texturised Vegetable Protein (TVP)

- Food ingredients

- Snack

- Breakfast cereals

See it in action

See the MPF24 small batch twin Screw extruder in action, perfect for lab-scale production, precise ingredient dosing, and small-batch snack development with easy cleaning and reliable scale-up.

- Overview

- Features

- Specifications

- Gallery

The MPF24 small batch twin screw extruder is designed for precise small-scale production and product development, providing flexibility for testing new ingredients, flavours, and colours. It combines reliable process control, scalable results, and high product versatility to support consistent, high-quality snack production.

High precision, reliable scale-up

The extruder’s clam-shell barrel and co-rotating, self-wiping segmented agitators allow operators to monitor and optimise processing conditions. Screw geometry is compatible with Baker Perkins’ production-scale extruders, ensuring reliable scale-up from laboratory trials to full production.

Easy to operate

Advanced PLC touch screen controls provide recipe management, data capture, and trending functions. Variable speed servo drives for agitators and cutters allow precise process control, while dry powder and liquid feed systems ensure accurate ingredient dosing.

Flexible product range

The MPF24 handles a wide variety of products, from simple direct-expanded curls, rings, and puffs to complex multi-component premium snacks. Flavours and colours can be added easily, supporting small batch production and market testing.

- Small-batch production and product development capability

- Dry powder and liquid feed systems for precise dosing

- Clam-shell barrel for easy access, monitoring, and cleaning

- Co-rotating, self-wiping segmented agitators for consistent mixing

- PLC touchscreen with recipe management and data capture

- Single-hole insert die with machine-mounted variable-speed cutter

- Electrically heated and water-cooled barrel

- Industry 4.0 ready for seamless data integration

- Reliable scale-up to full production extruders

- Nominal barrel length: 25:1 L/D (up to 40:1 L/D in 5:1 increments)

- Liner bore diameter: 24 mm

- Maximum operating temperature: 200 °C

- Maximum operating pressure: 1,250 psi

- Liner material: Through-hardened steel (nitrided D2)

- Barrel opening method: Manual

- Agitator speed range: 0–1,000 rpm

- Drive: 9.2 kW @ 1,000 rpm variable speed

Download

brochure

To learn more about the MPF24 small batch twin screw extruder by Baker Perkins, please download our PDF documentation.

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.