Versatile filled snack solutions

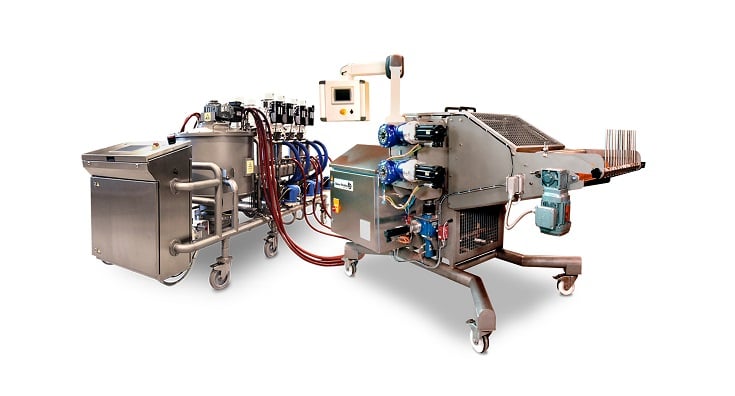

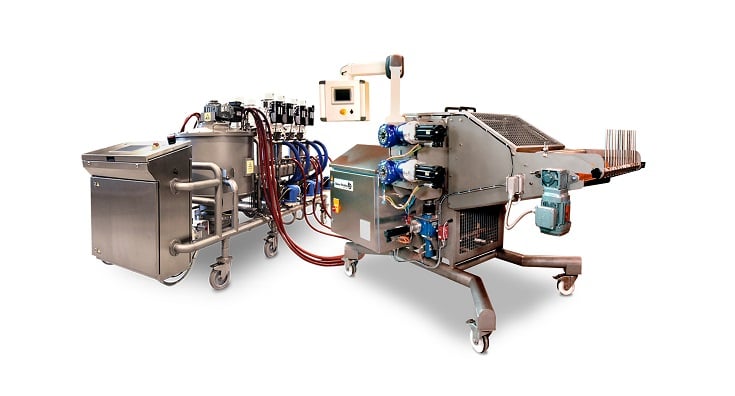

The CoEx Master™ co-extrusion system from Baker Perkins upgrades any twin-screw extruder into a line for high-value, center-filled snacks. Compact, versatile, and easy to integrate, it delivers precise weight control, consistent quality, and fast return on investment through advanced co-extrusion, cream feed, and crimping technology.

The TruClean™ gauge roll machine is ideal for:

- High-value filled snacks

- Sweet or savory center-filled products

- Innovative cereal or dough-based creations

End product applications:

- Filled pillows

- Filled shapes

- Filled wafers

- Filled bars

See it in action

Watch how the co-extrusion die, cream feed, and pillow crimper work together to deliver consistent quality, precise weight control, and a wide range of innovative products.

- Overview

- Specifications

- Gallery

The CoEx Master™ co-extrusion system upgrades any twin-screw extruder into a complete line for high-value, center-filled snacks. Combining co-extrusion die, cream feed, and pillow crimper, it ensures precise weight control, consistent product quality, and efficient operation, while remaining easy to clean and maintain.

High quality, low cost

The system delivers repeatable precision and reliable performance, minimizing waste and downtime. Adjustable streams, temperature-controlled cream feed, and servo-driven crimping rolls ensure consistent product dimensions and filling accuracy.

Easy to operate

Operators can monitor and adjust settings via an intuitive HMI. Independent servo motors allow precise roll and gap adjustments for repeatable, high-quality results.

Easy to clean and maintain

Hygienic design, portable components, and optional assisted cleaning system simplify sanitation. Separated infeeds, disassemblable pumps, and adjustable rolls allow quick cleaning and product changeover.

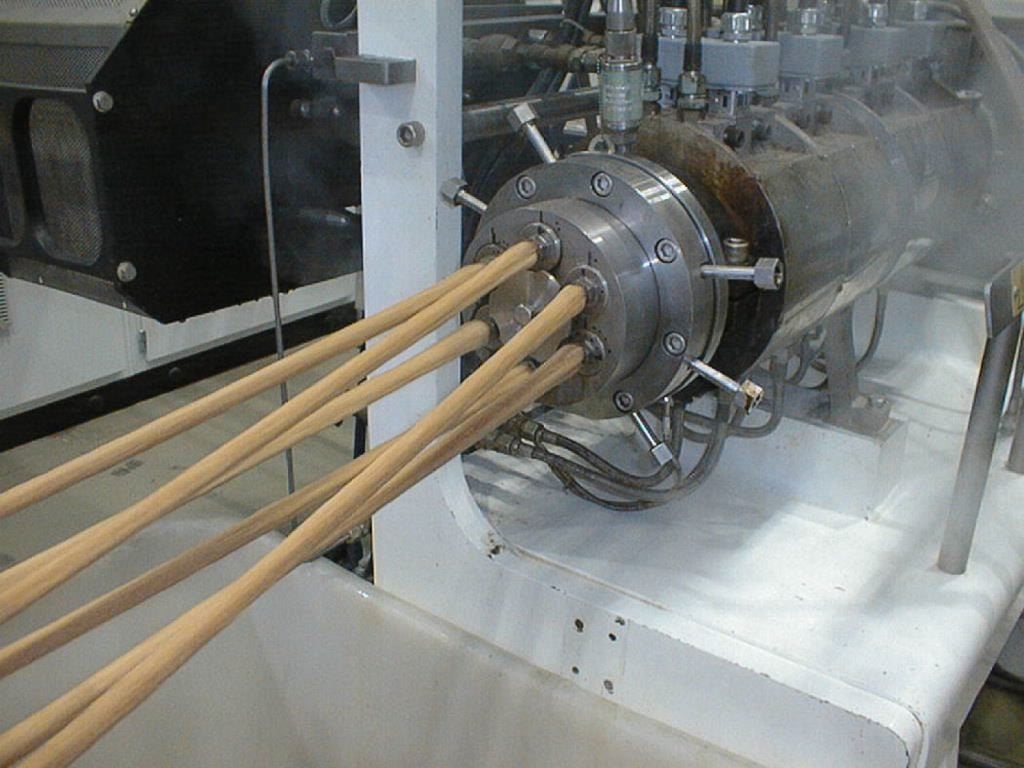

- Co-extrusion die

- Function: Combines extrudate and filling into concentric streams

- Adjustability: Each stream individually controllable for weight and consistency

- Streams available: 4, 6, 8, 12, or 16

- Materials: Stainless steel

- Cream feed

- Function: Stores and delivers center-filling to the co-extrusion die

- Temperature Control: Hopper with heating jacket and stirrer

- Pumps: Individual progressive cavity pumps for each stream (4, 6, or 8)

- Flow Control: Variable-speed screw with flow meters

- Holding Capacity: 300 L

- Materials: Stainless steel, hygienic design

- Pillow crimper

- Function: Crimps product streams into interlocking pillow shapes

- Rolls: Servo-driven adjustable crimping rolls

- Air Curtain: Prevents product sticking

- Flexibility: Multiple roll sets for different shapes and full cut-through capability

- Operation: Independent servo motors allow easy removal, replacement, and synchronization

- Materials: Stainless steel

Download

brochure

To learn more about the CoEx Master™ co-extrusion system by Baker Perkins, please download our PDF documentation.

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.