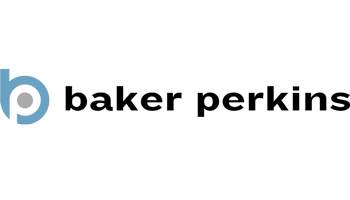

Food extruder for snacks, cereals, and food ingredient

The SBX Master™ twin-screw extruder from Baker Perkins efficiently produces a wide range of extruded foods and ingredients, from breakfast cereals and snacks to texturised vegetable protein and co-extruded products. Its versatile design delivers high output, consistent quality, and hygienic operation.

The SBX Master™ twin-screw extruder is ideal for:

- Breakfast cereals – flakes, curls, rings, balls, and filled cereals with co-extrusion

- Snacks – balls, curls, chipsticks, sheets, and innovative shaped or sheeted snacks

- Texturised Vegetable Protein (TVP) – burgers, minced meat, chicken pieces, sausages, meatballs, nuggets

- Food ingredients – breadcrumbs, croutons, crispy inclusions, fillings, pre-gelatinised or modified flours

See it in action

Discover the SBX Master™ twin-screw extruder– a versatile, high-output solution for breakfast cereals, snacks, texturised vegetable protein, and core food ingredients.

- Overview

- Features

- Gallery

The versatile SBX Master™ Twin-Screw Extruder has been designed with the flexibility to make a wide range of starch or protein-based products at high output and high efficiency. From the preconditioner, high-torque gearbox and agitator assemblies, every aspect of the machine has been optimized to provide flexibility with consistency, high quality and low production costs.

High outputs for extruded foods and ingredients

Segmented agitators, a heated/cooled modular barrel, a high-torque gearbox and a wide range of dies and cutting/forming options provide the capability to make any kind of extruded ingredient or food product.

Efficient, low-cost production

High-free volume screw geometry maintains output on fine-milled materials, while programmed routines reduce waste during start and stop. There is easy access for cleaning and maintenance, and a robust drive train for long service life.

Designed with hygiene in mind

The SBX Master™ is constructed from stainless steel with an open frame design and minimum open piping and cabling to make cleaning quick and simple, whatever the application.

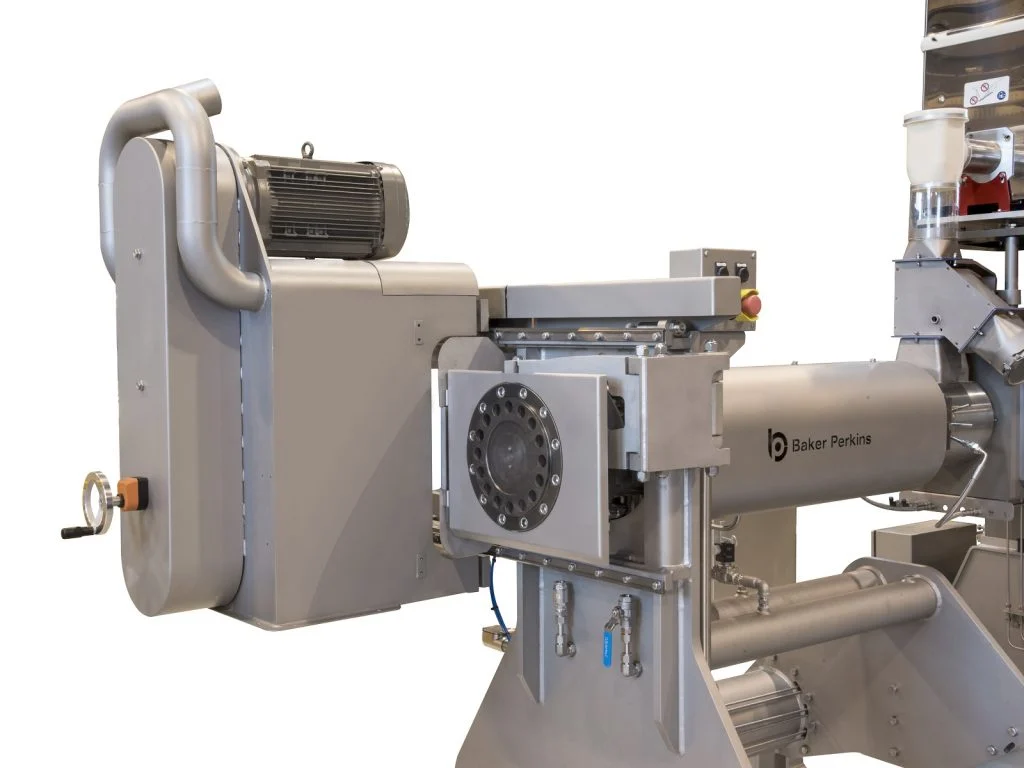

High-torque capacity gearbox

Improves reliability and increases range of products that can be made.

Gearbox condition monitoring system reduces unexpected downtime. A simple system continuously monitors the frequency and amplitude of vibrations within the gearbox, allowing the ongoing condition of vital components to be measured.

Powerful controls

PLC control with touch screen interface provides full process visualization, recipe edits, alarm management and start-up and shutdown sequencing.

Low-maintenance AC motor

With accurate speed and torque output that increase process control.

Open frame

For hygiene and easy cleaning.

Download

brochure

To learn more about the SBX Master™ twin-screw extruder by Baker Perkins, please download our PDF documentation.

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.