Gentle, high-capacity dough handling

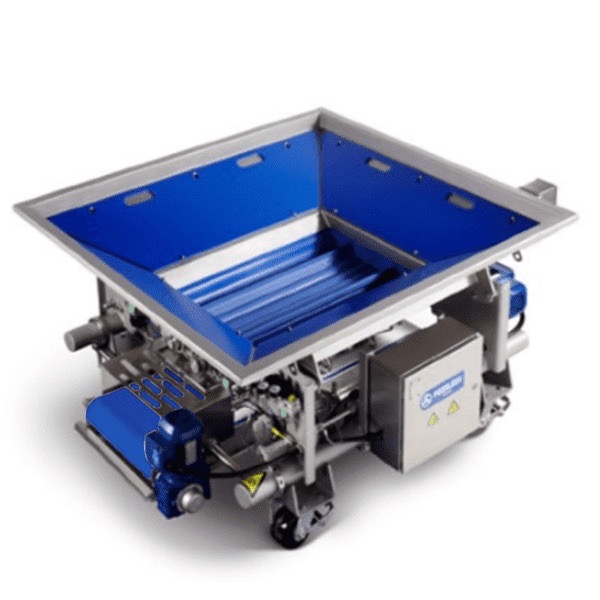

Peerless rotary dough feeder (RDF) is a gentle, high-capacity dough handling system that automatically feeds uniform blocks of dough to dividers or forming equipment without changing the dough’s temperature or structure.

Benefits:

- Maintains dough quality and consistency

- Eliminates manual dough handling and trough hoists

- Compact, portable, and quiet for confined areas

- Easy to clean with open, sanitary design

- High throughput up to 9,980 kg (22,000 lbs) per hour

See it in detail

Discover how the Peerless rotary dough feeder (RDF) improves dough handling efficiency and consistency.

- Overview

- Range

- Specifications

- Features

- Options

- Gallery

The rotary dough feeder ensures smooth, uniform transfer of dough from the mixer to downstream equipment, preserving product quality and maintaining precise feed rates. Its gentle rotary action prevents overworking or heating, making it ideal for bread, rolls, buns, bagels, and tortillas.

Efficient and flexible operation

Designed for efficiency, the RDF eliminates the need for large hoppers or manual trough handling. Multiple hopper capacities and cutter options allow customization for specific production needs. Optional power traverse and automated conveyors enable seamless feeding across multiple mixers or processing lines.

Hygienic and low-maintenance design

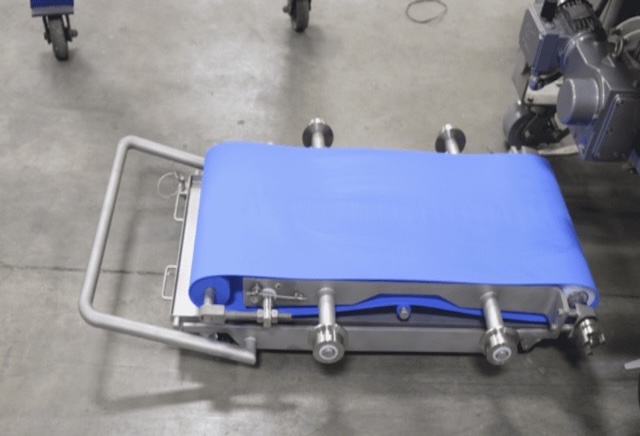

Built with a low-profile, open-frame design, the RDF simplifies sanitation and routine maintenance while fitting easily into tight production spaces. The polyethylene-lined hopper minimizes dough sticking, ensuring smooth discharge and easy cleaning for continuous, reliable operation.

| Model | Hopper capacity |

| RDF4 | 181 kg (400 lbs) |

| RDF6 | 272 kg (600 lbs) |

| RDF10 | 454 kg (1,000 lbs) |

| RDF16 | 726 kg (1,600 lbs) |

| RDF20 | 907 kg (2,000 lbs) |

| RDF24 | 1,089 kg (2,400 lbs) |

| RDF28 | 1,270 kg (2,800 lbs) |

| RDF32 | 1,451 kg (3,200 lbs) |

- Throughput: 226–9,980 kg (500–22,000 lbs) per hour

- Hopper capacity: 181–1,451 kg (400–3,200 lbs)

- Electrical: 460 V, 3 phase, 60 Hz (other configurations on request)

- Drive motor: 1 HP standard

- Model options: RDF4, RDF6, RDF10, RDF16, RDF20, RDF24, RDF28, RDF32

- Versatile dough compatibility – Handles bread, roll, biscuit, cracker, and cookie doughs.

- No manual handling required – Eliminates the need for trough hoists, trough handling, and large hoppers.

- Consistent dough feed – Maintains a constant dough level in the downstream hopper for improved scaling and forming accuracy.

- High-capacity throughput – Handles from 226–9,980 kg (500 lbs to 22,000 lbs) of dough per hour.

- Hygienic open design – Simplifies sanitation and routine maintenance.

- Compact and portable – Low-profile design fits easily in confined areas or where ceiling height is limited.

- Quiet and reliable – Operates smoothly with minimal noise for a better production environment.

- Power traverse for multiple mixers

- Vertical discharge and dough feed conveyors

- Integration with Automated Conventional Batch Mixer (ACBM®)

- Polyethylene-lined hoppers to minimize dough sticking

- Special hopper configurations for unique process layouts

Why choose the rotary dough mixer from Peerless?

“The mixer, in conjunction with the RDF (rotary dough feeder) and conveyor, have made our production process much more user-friendly. Our employees can produce significantly more product with greater efficiency, all while reducing physical stress.”

– OCHO Candy

Download

brochure

To learn more about the rotary dough mixer by Peerless, please download our PDF documentation.

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.