Fast module changeover & reliable material handling

Coperion K-Tron quick change feeder (QC) is a versatile, high-performance feeder designed for flexible handling of a wide range of bulk materials. Ideal for both continuous and batch processes, the QC feeder combines fast, easy changeovers with hygienic operation, helping prevent cross-contamination and minimize downtime.

The QC feeder is ideal for:

- Free-flowing powders, granules, and pellets

- Sticky or floodable powders

- Ingredients requiring frequent cleaning or quick switching

- Applications where one feeder must handle multiple materials efficiently

Benefits:

- Maximum flexibility for handling diverse bulk materials

- Quick and easy module changeover for minimal downtime

- Hygienic design reduces risk of cross-contamination

- Compatible with remote wet washdown cleaning

- Full compatibility with K2M feeder components

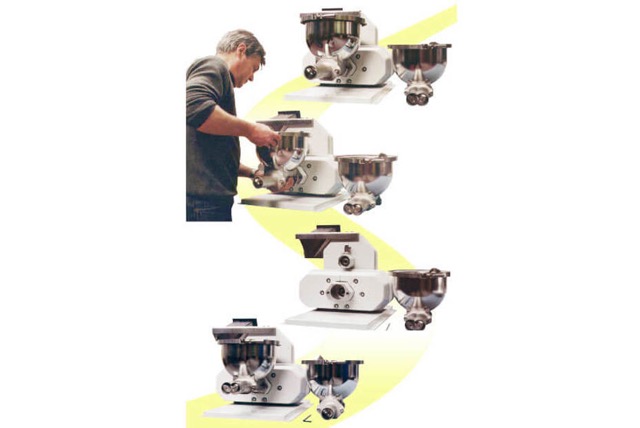

See it in action

See how the Coperion K-Tron quick change (QC) feeder enables fast, flexible, and hygienic feeding of powders, granules, and difficult-to-handle materials.

- Overview

- Features

- Gallery

Quick change (QC) feeders maintain smooth, continuous feeding by allowing rapid interchange of feeding modules while maintaining precise feed rates. This ensures reliable material handling and protects product quality, making them ideal for industrial, food, or pharmaceutical applications where multiple materials must be handled from a single station.

Designed for performance and reliability

Constructed from high-quality stainless steel with modular screw and feed bowl options, QC feeders deliver long-term accuracy and consistent operation. The quick-change design allows one module to be cleaned while another continues feeding, minimizing downtime and eliminating the risk of cross-contamination.

Compact, adaptable, and flexible

Available in T35 and S60 configurations, QC feeders can handle a wide variety of materials, from free-flowing powders to sticky or difficult-to-flow ingredients. Their modular design integrates easily into existing lines or tight spaces, and rapid changeover capability simplifies recipe or product transitions, boosting productivity.

Simplified cleaning and maintenance

Interchangeable feed bowls and screws are easy to remove for cleaning, supporting strict hygiene standards in food and pharmaceutical environments. Open-frame or enclosed configurations allow full accessibility for maintenance while reducing installation costs and process interruptions.

- Quick changeover – Switch between single and twin screw modules in minutes.

- Continuous operation – One module feeds while the other is cleaned.

- Versatile feeding – Single screws for free-flowing powders; twin screws for sticky or floodable materials.

- Flexible configurations – Supports T35 and S60 setups with various scales, hoppers, and screws.

- Precise feed rates – Adjustable per feeder type and material.

Feed rates depend on the feeder type and configuration >> Single screw feeder (S60) & Twin screw feeder (T35)