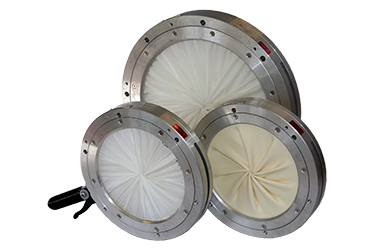

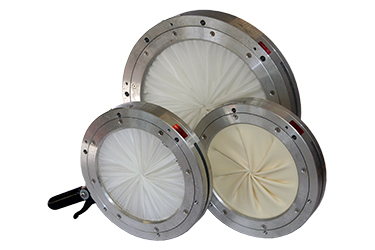

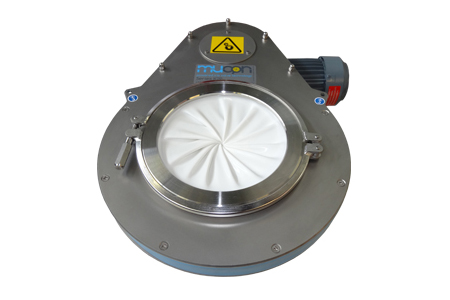

Iris diaphragm valves

Iris valves

for “trickle-feed” applications

Iris diaphragm flow control valves for precision powder handling

Mucon iris diaphragm valves give manufacturers accurate control of powders, granules, and delicate materials. These valves use a flexible diaphragm that closes smoothly from the center, allowing steady flow control from full discharge to a fine trickle. Due to their simple, reliable design makes them suitable for food, pharmaceutical, chemical, and general industrial applications.

Moreover, for other types of flow control valves for food & pharma industries, see our valve range here.

Valve ranges are also available for plastics, chemical, and mineral processing applications. For more details, please visit the valves page on the performance materials Coperion website.

Contact the Mucon technology brand team

Phone: +44 1625412000

- Features

- Range

- Diaphragm Selection

- installation

- Use of liners

- No product contact with mechanical components, so jamming does not occur.

- Full-bore openings that allow unrestricted flow.

- Fine “trickle-feed” control from maximum flow down to low-volume dosing.

- Hand, pneumatic, or motorized operation options.

- A slim, compact design that simplifies installation.

- No mechanical wear from abrasive materials.

- Dust-tight sealing for a cleaner working environment.

- The ability to seal around irregular objects.

- Hygienic options suitable for food and pharma.

- Easy daily operation and quick maintenance.

To help customers find the right solution, Mucon offers several models of iris diaphragm valves. Each series supports different applications and installation needs.

Selecting the right diaphragm material ensures safe, efficient, and long-lasting performance. Because of this, Mucon offers fabric, coated fabric, and rubber diaphragms for different material types, temperatures, and hygiene requirements.

In addition, the selection table below shows suitable materials for powders, granules, abrasive products, high-temperature applications, hygienic environments, and more.

| Diaphragm type | Fabric | Coated fabric | Rubber |

|---|---|---|---|

| Powder | Yes | Yes | |

| Granules | Yes | Yes | Yes |

| Abrasive | + | Yes | |

| Hygienic | Yes | ||

| Pressure | Yes | ||

| Vacuum | Yes | ||

| Temperature | Yes | ++ |

- Terylene is abrasion resistant

++ Viton Coated Terylene is ok for 200ºC.

Select most appropriate material using the diaphragm selection guide.

Diaphragm selection guide

| Application | Food quality white rubber | Red rubber | Anti-static rubber | Mock leno | Nylon | Anti-static nylon | Hypalon coated nylon | Poly-urethane coated nylon | Teflon | Terylene | Vitron coated terylene |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Powder below 150 mesh (104 microns) | •• | •• | •• | •• | •• | •• | •• | ||||

| Granules over 150 mesh | • | • | • | • | • | • | • | • | • | • | • |

| Lumps | •• | •• | •• | • | • | • | • | • | • | • | • |

| Slurry | Under 1M header | Under 1M header | Under 1M header | • | • | • | • | ||||

| Liquid | Under 1M header | Under 1M header | Under 1M header | • | • | • | • | ||||

| Air or gas | • | • | • | • | |||||||

| Abrasion resistance | • | •• | • | • | • | • | •• | •• | |||

| Acid | • | • | • | ||||||||

| Alkali | • | • | • | • | • | • | • | • | • | ||

| Max Temperature | 70ºC | 70ºC | 70ºC | 70ºC | 110ºC | 110ºC | 120ºC | 100ºC | 250ºC | 130ºC | 200ºC |

| Min Temperature | -40ºC | -40ºC | -40ºC | -40ºC | -75ºC | -75ºC | -35ºC | -40ºC | -75ºC | -75ºC | -40ºC |

| Pressure or vacuum | Below 0.14 bar | Up to 0.20 bar | |||||||||

| Food or pharm | •• | • | • | • | • | •• | • | ||||

| Infestation or mold growth | • | • | • | • | • | •• | •• | ||||

| Dangerous static | • | ||||||||||

| Hygroscopic | •• | •• | • | • | |||||||

| Oil or fat content | • | • | •• | • | • | • | • | ||||

| Poor flow | •• | •• | •• | ||||||||

| Flammability | Inflammable | Inflammable | Inflammable | Inflammable | Will not propagate a flame | Inflammable | |||||

| Weather resistance | Good | Excellent | Good | Very Good | Slow loss of strength | Excellent | Excellent | Excellent | Slow loss of strength | Good | |

| Tensile strength kgs/cm² | 120 | 120 | 120 | 5.625 | 4.6 | 25% above base material | 25% above base material | 4.6 | 6.400 | 6.400 | |

| Elongation & break | 700% | 700% | 700% | 25% | 25% | 25% | 25% | 13% | 30% | 30% | |

| Cost factor 1-lowest 5-highest | 2 | 2 | 5 | 1 | 1 | 1 | 1 | 1 | 5 | 1 | 5 |

| Availability 1-best 5-worst | 1 | 1 | 5 | 3 | 1 | 4 | 3 | 1 | 4 | 2 | 4 |

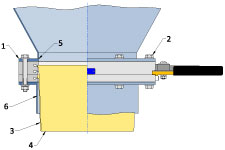

The diagram below shows the recommended way to install Mucon Iris Diaphragm Valves (IDVs). When these steps are followed, the diaphragm lasts much longer. The AD, JS, and K Series have lever slots that let the control levers move through 180°, so they need a mix of through-bolts and set screws during installation.

However, any misalignment between the valve and the ductwork can affect how the lever moves. Even a small misalignment may cause the slot to open or close. If the misalignment is more serious, it can put stress on the valve body. As a result, some parts may wear out quickly or fail early. Each valve also has a label that shows the correct material-flow direction to support proper installation.

To ensure proper installation and long-term performance, follow these recommendations:

- Ensure all flanges remain flat and free from distortion.

- Prevent bolts from protruding into the lever slots.

- Provide 12 mm of clearance at the base when the diaphragm is fully open.

- Make the inlet diaphragm 5 mm smaller than the valve inlet.

- Make the discharge opening 10 mm larger than the valve outlet.

Liners can greatly improve iris diaphragm valve performance by protecting components, reducing wear, and supporting smoother material flow. They provide three main benefits:

- Hygienic and protective barrier

- Assisting diaphragm opening

- Reducing diaphragm wear

1. Use as a hygienic or protective liner

By inserting a liner through the diaphragm of a Mucon iris valve, you can keep valve components such as the body, clamp ring, and diaphragm away from harmful or hazardous powders. This creates a safer and more controlled process.

Typical applications include:

- When the iris valve is lined, the powder contacts only smooth surfaces. This makes the system more hygienic and easier to clean. It is especially useful in food, pharmaceutical, and other applications where powder build-up is not acceptable.

- Lining the valve to protect components from corrosive or damaging powders.

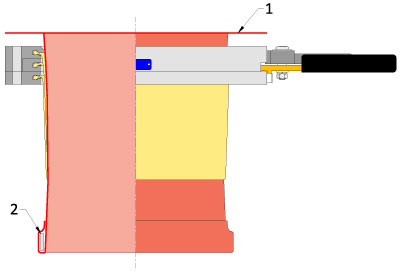

2. Liners to assist diaphragm opening

Where a fabric diaphragm is specified, it is always necessary to have a certain weight of material acting downwards to make it open fully. If the material has a tendency to bridge, often the diaphragm will only partially open.

If a flanged liner is hung through the valve (1) with weights of stainless steel sewn in the hem of the liner (2), this will assist in opening. (See illustration)

Liners also make valve operation easier. Some free-flowing powders create high static loads on the diaphragm, causing:

- Diaphragm layers pressing tightly together, increasing friction

- Product in the column trying to rotate as the valve opens

A liner reduces these effects, improving opening performance and lowering operating effort.

3. Liners to combat diaphragm wear

Diaphragm life depends on operating frequency, product volume, and abrasive properties. When diaphragms wear quickly, a liner provides an additional sacrificial layer.

Common solution:

LINATEX® rubber liners, which offer exceptional abrasion resistance. For in-line systems, a double-flange liner provides extra protection.

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.

Interested about this topic?

Follow Coperion’s Food Health & Nutrition social media channels to receive updates and videos about our latest technologies and product applications.

>> LinkedIn

>> Youtube

>> Instagram