IBC liquid tote handling system with

seamless production

The Shick Esteve IBC liquid tote system is a sanitary liquid tote transfer system designed for hygienic, uninterrupted liquid ingredient handling. Ideal for managing oils, sweeteners, and yeast, it ensures seamless tote changeovers without halting production.

The Shick Esteve IBC liquid tote system is ideal for:

- Continuous liquid ingredient supply with tote changeover flexibility

- Hygienic transfer of oils, sweeteners, and dairy-based ingredients

- Compact spaces needing stackable or tilting tote configurations

- Automated or manual systems with level-sensing and flow metering

- Applications requiring sanitary, food-grade componentry

- Overview

- Models

- Options

- Gallery

The Shick Esteve IBC liquid tote system (IBCs) is a sanitary, efficient solution designed to store and transfer a variety of liquid ingredients such as oils, sweeteners, yeast, and more. The system integrates totes feeding a surge tank with a pump that distributes ingredients to one or multiple use points, allowing continuous production even during tote changeover. Ideal for food and beverage manufacturing, it provides reliable, hygienic ingredient handling with minimal downtime.

Continuous, hygienic liquid handling

Equipped with inline level switches and surge tanks, the system allows operators to replace empty totes without interrupting production, ensuring seamless operation and additional changeover time.

Flexible and adaptable design

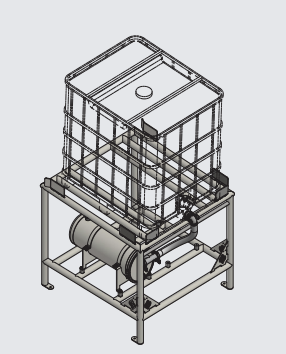

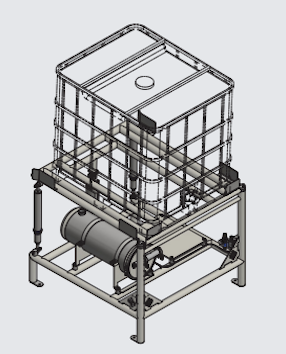

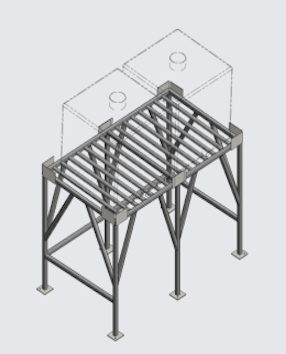

Typical tote connections use 2” food-grade hoses with cam-lock and tri-clamp connectors. The system’s stainless steel frame is angled for optimal drainage and designed for sanitary environments.

Built for cleanability and reliability

The surge tanks feature vacuum breakers and air bleeds in standard 57L (15 gallon) and 114 L (30 gallon) sizes, with multiple pump options including centrifugal, positive displacement, and diaphragm pumps, tailored to processing needs.

Optional features

- Sanitary inline reservoir (304 S/S with vacuum breaker/air bleed), available in 14, 20, and 45-gallon sizes with level switch

- Sanitary strainers for contaminant removal

- Sanitary magnet traps for metal detection

- Mass flow meters for precise ingredient measurement

- Tank heaters to maintain optimal ingredient temperature

- Tilt feature for improved drainage and easy cleaning

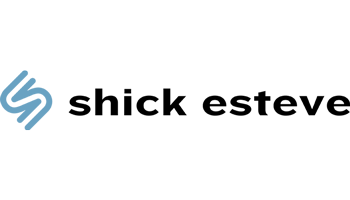

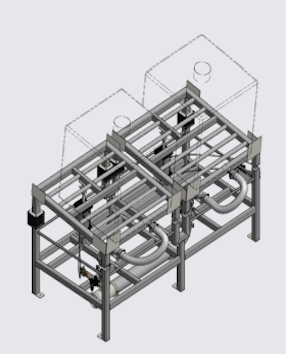

- Dual gravity/double-stacked tote configuration for uninterrupted production and space efficiency

- Lockable casters for mobility and flexible plant layout

Frame options

- Open-frame stainless steel design for easy access and cleaning

- Custom frame configurations available upon request to suit specific facility requirements

Download

brochure

To learn more about the IBC liquid tote system by Shick Esteve, please download our PDF documentation.

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.