fine sugar applications

Fine sugar manufacturing technology

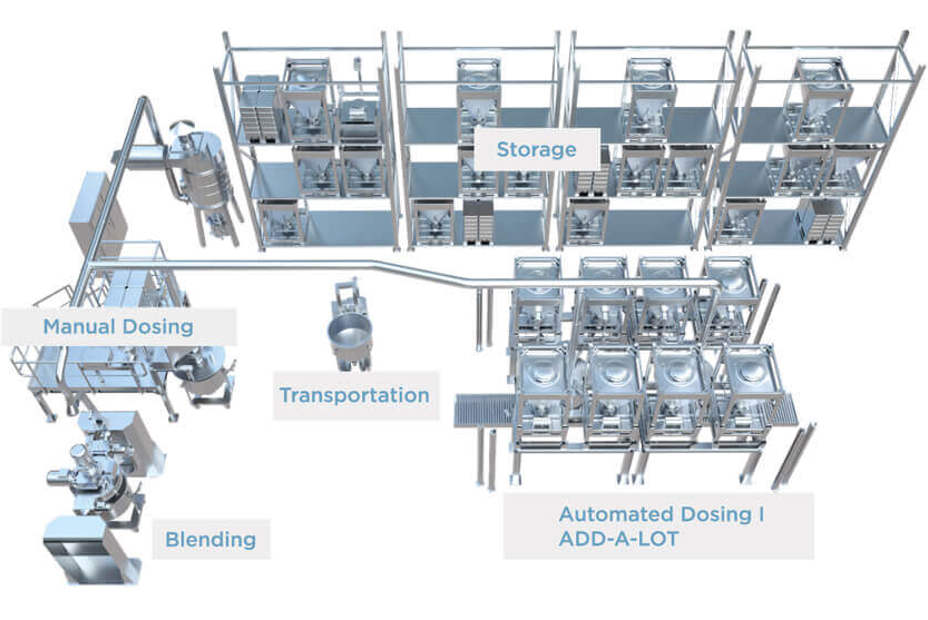

Coperion offers fully integrated, fine sugar production systems designed to deliver precise dosing, fast changeovers, and hygienic processing. Our advanced technology supports consistent quality and efficiency for fine sugar used in food, health, and pharmaceutical industries.

Advanced solutions for fine sugar applications

Fine sugar, used in baking, confectionery, beverages, and industrial food production, is processed efficiently with advanced dosing and handling technology, ensuring consistent quality and performance.

Coperion’s equipment provides precise control over sugar flow, particle size, and blending, supporting both traditional recipes and innovative product formulations.

From standard baking applications to complex confectionery or beverage recipes, our integrated systems deliver consistent results, smooth scalability from lab trials to full production, and flexibility for incorporating inclusions, flavours, or custom formulations.

How fine sugar production works

(MIH systems)

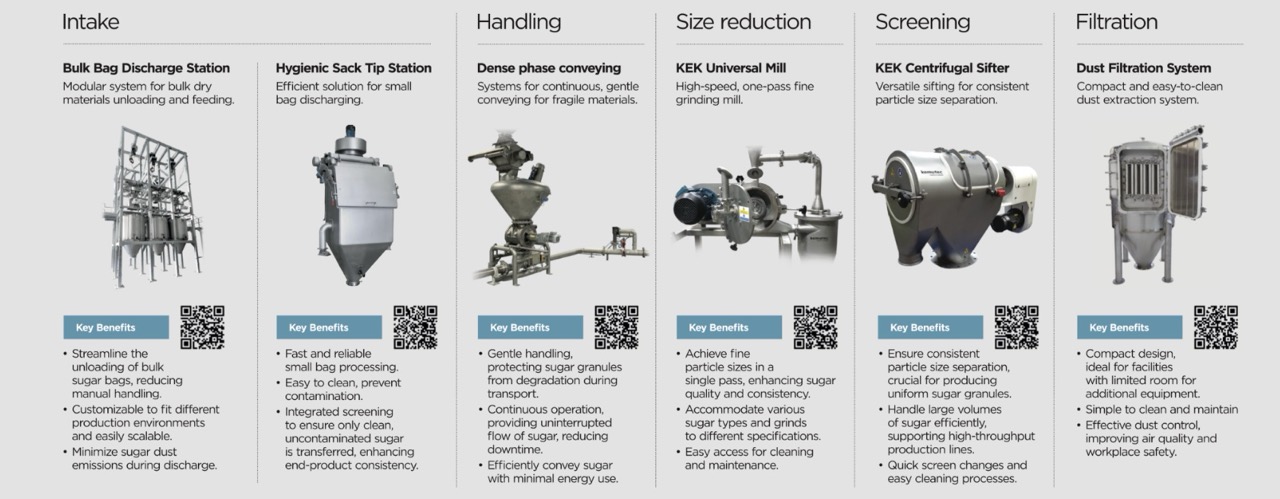

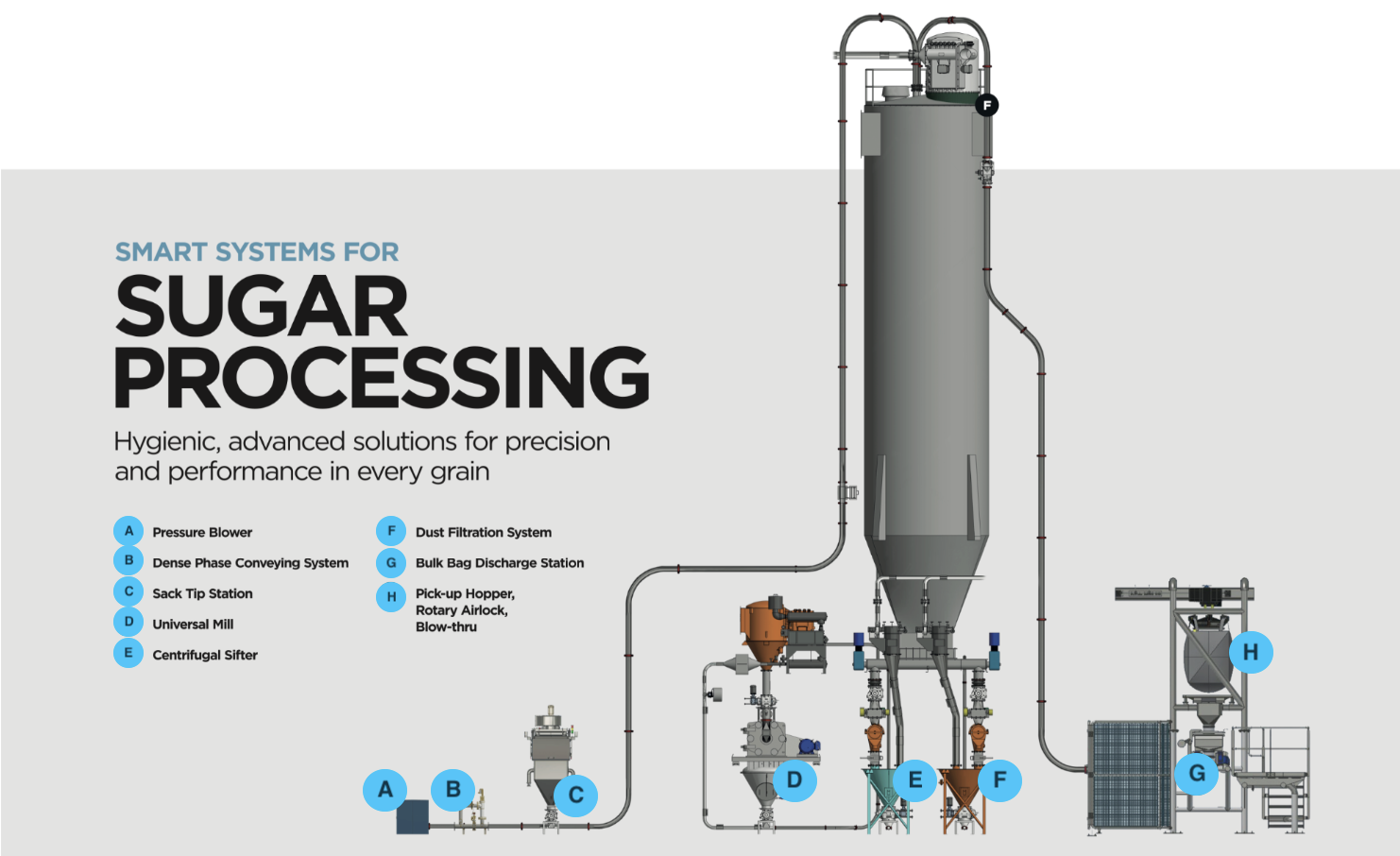

Ingredient intake

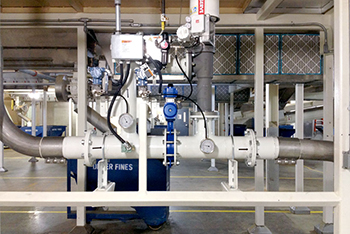

The sugar handling process starts with unloading raw materials. Bulk sugar bags are discharged using a bulk bag discharge station, which reduces manual handling and minimizes dust emissions. For smaller sugar bags, a hygienic sack tip station is used, integrating screening to ensure only clean, uncontaminated sugar enters the production line. These systems ensure that all raw ingredients are safely handled, hygienic, and consistently delivered for further processing.

Ingredient handling

After discharge, sugar is transported gently through a dense phase conveying system, which protects fragile granules from damage while providing a continuous flow to downstream equipment. This approach reduces downtime and ensures smooth, energy-efficient movement of materials throughout the plant.

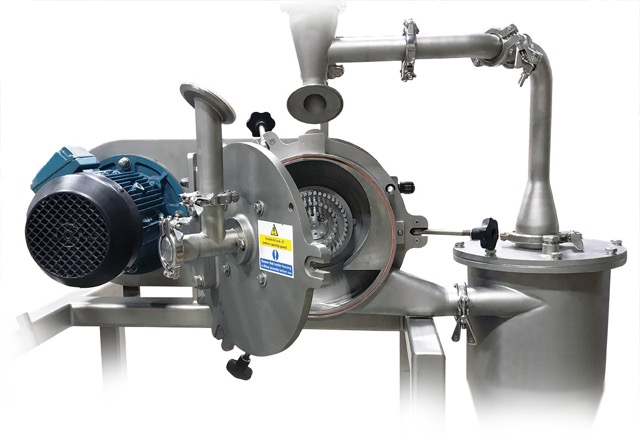

Size reduction

Sugar and other ingredients can be processed using a variety of KEK milling technologies from Kemutec, depending on the material type and the desired particle size. These mills provide consistent grinding, de-lumping, and sizing, handling everything from coarse to ultra-fine powders. They are suitable for both dry and wet materials, offering flexibility for different recipes and production requirements.

Milling options include:

PPS air classifier mill – for ultra-fine grinding of delicate or heat-sensitive powders, including dairy powders and gluten.

KEK kibbler – for heavy-duty lump breaking and reclaiming candies or baked goods.

KEK cone mill – for grinding, de-lumping, and sieving powders like sugar, spices, or flavours.

KEK universal mill – for high-speed, one-pass grinding to produce consistent sugar or ingredient particle sizes.

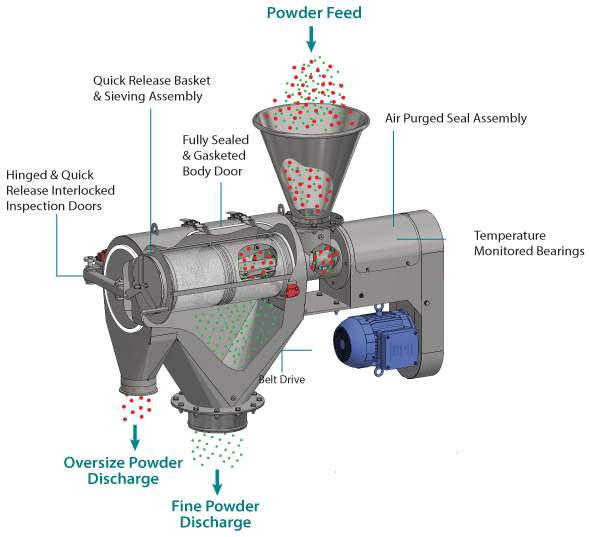

KEK centrifugal sifter

Screening

The ground sugar is then separated by particle size using a KEK centrifugal sifter, ensuring uniform granule size. The sifter handles large volumes efficiently, supports high-throughput production, and allows quick screen changes and cleaning.

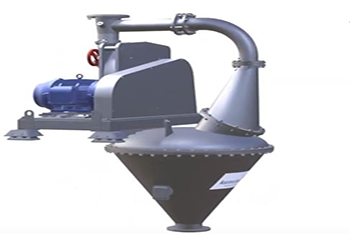

Filter receiver for pneumatic conveying systems

Filtration

Throughout handling, grinding, and screening, a dust filtration system captures airborne sugar particles, improving air quality and workplace safety. Its compact, easy-to-clean design makes it suitable even for facilities with limited space.

Related technologies

Related fine sugar applications

Get in touch

We take a distinctive approach to the processes that drive manufacturing. Let us know how we can help you achieve your goals for efficiency, productivity and safety.