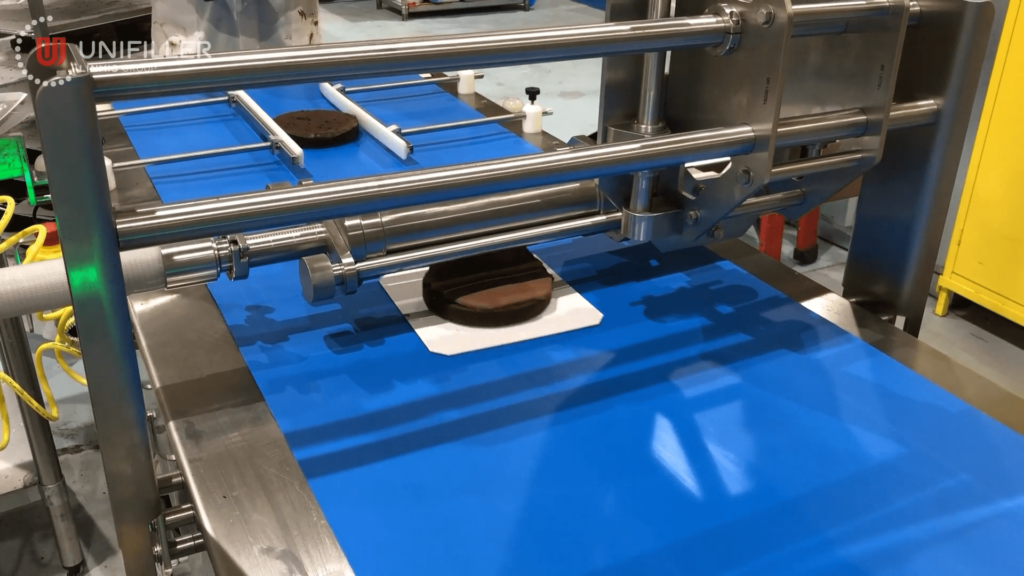

The Unifiller ACIS line is a fully automated cake icing system engineered for industrial bakeries requiring high-speed, precise, and consistent decorating. It mid-fills, top and side ices, and finishes cakes with accuracy, handling up to 8 – 12 cakes per minute with buttercream or whipped toppings.

Reliable performance for automated cake decorating

The ACIS reduces manual labor by automating layer placement, mid-filling, and icing applications. Designed for large-scale production, it ensures uniform quality, reduces operator strain, and increases throughput in demanding bakery environments.

Hygienic design and easy operation

Built with an easy washdown system and tool-free adjustments, the ACIS supports quick cleaning and fast product changeovers. Operators benefit from a touchscreen interface, computerized production speeds, and real-time performance monitoring for reliable control.

Flexible integration and smart operation

Configurable to different production needs, the ACIS offers adaptable deposit ranges and particle sizes for versatile applications. Power requirements include air at 6 CFM @ 80 psi and electrical options of 110 or 220 VAC, ensuring seamless integration into bakery production lines. Optional modules, such as a Servo Layer Cake System or Cake Stacker, further enhance efficiency for round cake production.

- Speed: Up to 8-12 cakes per minute

- Deposit Range: Configured to product needs

- Particle Size: Configured

- Power: Air – 6 CFM @ 80 psi | Electrical – 110 or 220 VAC

- Washdown: Easy washdown

- Tools: No tools required