Heavy-duty dough chunker designed to support dividers and forming lines

Shaffer® dough chunker is engineered to feed consistent chunks of dough from the mixer area to downstream dividers or forming equipment. Built for bakeries producing a wide range of products from bagels and sweet doughs to frozen dough and health bars, these systems ensure uniform dough handling, flexible integration, and hygienic design.

With models supporting batch capacities from under 272 kg (600 lb) to over 1,588 kg (3,500 lb) and production rates exceeding 13,154 kg/hr (29,000 lb/hr), Shaffer® dough chunker is suited for both mid-size and large-scale operations. Features like variable frequency controls, stainless steel hoppers, and wash-down compatibility offer bakeries a reliable and sanitary solution for continuous dough processing.

Each system is constructed on a heavy-duty stainless steel frame with casters for mobility and features a sloped dough hopper for smooth, consistent flow.

Highlights:

- Heavy-duty stainless steel frame on casters

- Sloped stainless steel dough hopper

- Variable frequency controls for line speed matching

- Removable discharge conveyor for easy cleaning

- Wash-down design with NEMA 4X enclosures

Ideal uses include:

- Bread and sandwich loaves

- Buns, rolls, and frozen dough

- Pizza crusts and flour tortillas

- Sweet doughs, bagels, and health bars

- Pet food and other specialty doughs

- Overview

- Range

- Features

- Gallery

- Resources

Shaffer® Dough Chunker is designed to improve dough transfer efficiency between mixing and forming stages in high-throughput bakery operations. The sloped hopper design ensures steady feeding, while options like integrated conveyors and dough sensors support a seamless transition between processes. With a focus on hygiene and durability, these machines are built to meet the demands of 24/7 production environments.

Reliable performance across batch sizes

With hopper volumes from 340 to 1,810 L (12 to 64 cu ft) and maximum dough capacities up to 1,597 kg (3,520 lb), Shaffer® Dough Chunker can be configured to match your bakery’s specific output needs. Models are available to support processing rates over 13,154 kg/hr (29,000 lb/hr).

Hygienic construction for industrial environments

Each system is made with a heavy-duty stainless steel frame and wash-down-ready enclosures (NEMA 4X), with BISSC, UL, cUL, ANSI, USDA, and CE compliance. Removable discharge conveyors and optional hopper oilers further support clean operation and reduced maintenance time.

Operator-friendly controls and integration options

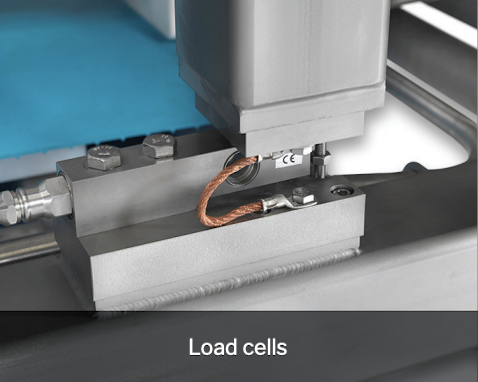

Shaffer® Dough Chunker is equipped with variable frequency controls to sync with downstream equipment speeds. Optional integrated mixer controls, dough level sensors, and load cells enable more precise automation and real-time performance monitoring.

| Model | Hopper volume | Hopper capacity | Max production rate |

|---|---|---|---|

| RDC6 | 0.34 m³ (12 cu ft) | 300 kg (660 lb) | 5,352 kg/hr (11,800 lb/hr) |

| RDC8 | 0.45 m³ (16 cu ft) | 400 kg (880 lb) | 5,352 kg/hr (11,800 lb/hr) |

| RDC10 | 0.57 m³ (20 cu ft) | 500 kg (1,100 lb) | 5,352 kg/hr (11,800 lb/hr) |

| RDC13 | 0.74 m³ (26 cu ft) | 650 kg (1,430 lb) | 4,400 kg/hr (9,700 lb/hr) |

| RDC16 | 0.91 m³ (32 cu ft) | 800 kg (1,760 lb) | 8,940 kg/hr (19,700 lb/hr) |

| RDC20 | 1.13 m³ (40 cu ft) | 1,000 kg (2,200 lb) | 13,400 kg/hr (29,560 lb/hr) |

| RDC25 | 1.42 m³ (50 cu ft) | 1,250 kg (2,750 lb) | 13,400 kg/hr (29,560 lb/hr) |

| RDC28 | 1.59 m³ (56 cu ft) | 1,400 kg (3,080 lb) | 13,400 kg/hr (29,560 lb/hr) |

| RDC32 | 1.81 m³ (64 cu ft) | 1,600 kg (3,520 lb) | 13,400 kg/hr (29,560 lb/hr) |

Main features

- Heavy-duty tubular stainless steel frame construction, mounted on heavy-duty casters

- Stainless steel sloped dough hopper

- Dual UHMW dough augers for uniform feeding and gentle degassing

- Belt drive design for universal pump positioning and discharge

- Variable frequency controls to match downstream equipment line speeds

- Production rates: up to 6,800 kg/hr (≈ 15,000 lb/hr)

Additional features

- Production rates over 13,150 kg/hr (≈ 29,000 lb/hr) on standard models

- UL and cUL compliant controls

- BISSC certified

- ANSI, USDA, and CE compliant

Optional features

- Vertical or incline dough conveyors (mounted or independent)

- Dough level sensor

- Manual or automatic traversing system

- Back splash protection

- Operator controls integrated with mixer

- Dough thermometer and hopper oilers

- Load cells for dough weight monitoring

- Light curtains or perimeter guarding for safety

- STONEKOTE®-coated cutters for smooth dough release

Download

brochure

To learn more about the dough chunker by Shaffer, please download our PDF documentation.

Request a quote

Our sales team is standing by to help you find and procure the right equipment for your process requirements.